Unveiling the Mystery of Mirror Substrate Manufacturing: A Comprehensive Guide

Unveiling the Mystery of Mirror Substrate Manufacturing: A Comprehensive Guide

In the world of glass and mirrors, the process of creating Mirror Substrates remains one of the most fascinating yet least understood aspects. Here at Hiking Glass & Mirror, we are committed to shedding light on this intricate process, helping our clients gain a deeper understanding of what goes into producing high - quality mirrors. In this article, we will explore the key steps and considerations involved in mirror substrate manufacturing, addressing common concerns and providing valuable insights to assist you in making informed decisions.

The Importance of Mirror Substrate Quality

For export - oriented companies like ours, delivering mirrors that meet international standards is paramount. The quality of the mirror substrate directly impacts the performance and longevity of the final product. A superior substrate ensures better reflection, durability, and resistance to environmental such factors as humidity and temperature fluctuations. However, many clients are unaware of the critical factors that determine substrate quality, often leading to dissatisfaction with their purchases.

Selecting the Right glass for mirror Substrates

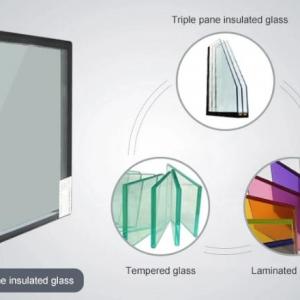

The journey begins with choosing the appropriate glass. The type of glass used as the substrate affects various properties of the mirror. Float glass is a popular choice due to its smooth surface and uniform thickness. It provides an excellent base for the subsequent coating processes. On the other hand, textured glass can offer unique aesthetic appeal but may require additional processing to achieve the desired mirror effect.

When selecting glass, it is essential to consider factors such as transparency, surface flatness, and chemical composition. Impurities in the glass can lead to imperfections in the mirror, affecting its optical performance. Our team at Hiking Glass & Mirror works closely with glass suppliers to ensure that we source only the highest quality materials for our mirror production.

The Coating Process: Heart of Mirror Manufacturing

The coating process is where the magic happens in mirror manufacturing substrate. This involves applying a reflective layer onto the glass surface. Traditionally, silver has been the primary material used for this purpose due to its excellent reflective properties. However, advancements in technology have introduced alternative coatings such as aluminum and dielectric coatings, each with its own set of advantages.

During the coating process, precise control over factors like temperature, pressure, and coating thickness is crucial. Any deviations can result in uneven reflection or reduced durability of the mirror. We utilize state - of - the - art coating equipment and employ skilled technicians who meticulously monitor the process to guarantee consistent quality.

Ensuring Durability through Protection

Once the reflective coating is applied, the mirror substrate needs protection. This is typically achieved by adding a protective backing layer. The choice of backing material depends on the intended application of the mirror. For Decorative mirrors, a thin protective film might suffice, while for industrial or outdoor use, a more robust backing such as a polymer film or a layer of paint is often required.

The protective layer serves to prevent the reflective coating from being scratched, corroded, or damaged by environmental elements. At Hiking Glass & Mirror, we offer a variety of protection options tailored to different client needs, ensuring that our mirrors remain in pristine condition throughout their lifecycle.

Quality Control: The Guardian of Excellence

Throughout the mirror substrate manufacturing process, rigorous quality control measures are implemented. From the initial glass inspection to the final product testing, our quality control team leaves no stone unturned. We conduct visual inspections to detect any surface defects, perform reflectivity measurements to ensure optimal performance, and carry out durability tests such as humidity and temperature resistance tests.

By maintaining stringent quality standards, we not only meet but often exceed our clients' expectations. Our commitment to quality has earned us a reputable position in the export market, with clients returning for our reliable and high - performance mirror products.

Common Challenges and Solutions in Mirror Substrate Manufacturing

Clients often encounter challenges when sourcing mirror substrates. One common issue is the variation in quality between different suppliers. To address this, we recommend establishing long - term partnerships with suppliers who demonstrate consistent quality and transparent manufacturing processes.

Another challenge is understanding the specific requirements for different mirror applications. For instance, mirrors used in automotive applications have different standards compared to those used in furniture. Our team at Hiking Glass & Mirror is always ready to assist clients in navigating these complexities, providing expert advice to help them select the most suitable mirror substrates for their projects.

The Future of Mirror Substrate Technology

As technology continues to advance, so does the field of mirror substrate manufacturing. Innovations such as smart mirrors with electronics integrated and eco - friendly mirror coatings are emerging. These developments promise to expand the applications of mirrors and provide more sustainable solutions for our clients.

At Hiking Glass & Mirror, we are at the forefront of embracing these new technologies. We invest in research and development to explore we how can incorporate these advancements into our production processes, ensuring that we stay ahead of the curve and continue to deliver cutting - edge mirror products to our global clientele.

We hope this article has provided you with valuable insights into the world of mirror substrate manufacturing. Understanding this process can empower you to make better purchasing decisions and appreciate the craftsmanship behind each mirror. We invite you to share your thoughts, experiences, or questions in the comments below. Your feedback is invaluable to us as we strive to enhance our services and products. Together, let's continue to explore the fascinating realm of glass and mirrors!

English

English Russian

Russian