When purchasing a shower room, most people mainly consider factors such as frame material, explosion-proof glass and price, and often ignore the choice of stainless steel glass clamps accessories.

The glass clamp fittings accessories of the shower room are inconspicuous compared to the large-area materials such as glass and frame. However, in the actual use of the shower room, glass clamp fittings accessories are a crucial factor affecting the life and experience of the shower room. No matter how well the glass and frame materials are selected, after a year of use, the hinges are rusted, loose, or the slide rails are stuck, not to mention how depressing it is. Therefore, in the choice of shower room glass clamp fittings accessories, be sure to polish your eyes.

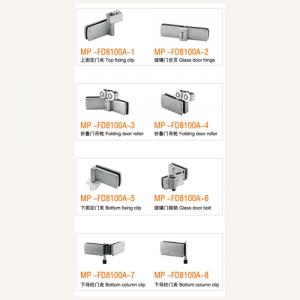

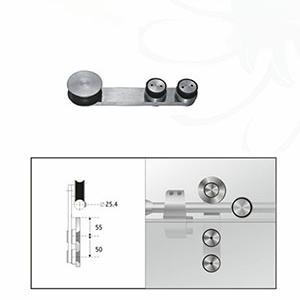

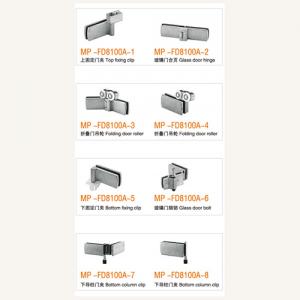

Common glass clamp fittings accessories in mainstream shower rooms mainly include: shafts, hinges, pulleys, guide rails, handles, water barriers, etc.

1. Rotating shaft and stainless steel glass clamps

2. Guide rails and pulleys

3. Handle

4. Water retaining strip

English

English Russian

Russian