Loking for a laminated glass factory,safety glass company,blast resistant glazing factory?

Domestic architectural laminated tempered glass is recognized as safety laminated tempered glass: tempered laminated tempered glass, laminated laminated tempered glass. Due to the physical properties of self-explosion of tempered white laminated glass, tempered white laminated glass still has potential safety hazards to a certain extent. Compared with ordinary tempered white laminated glass, laminated white laminated glass has more reliable safety performance. It will not fall off by itself after self-explosion or being broken, which can ensure the safety of pedestrians or objects under the building within a certain period of time. Laminated white laminated glass is a combination of two or more toughened laminated glass substrates (tempered or non-tempered toughened laminated glass) sandwiched between them through different lamination processes.

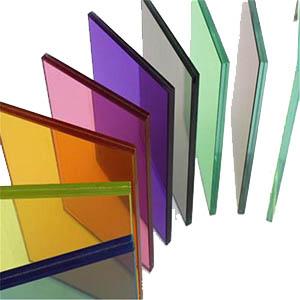

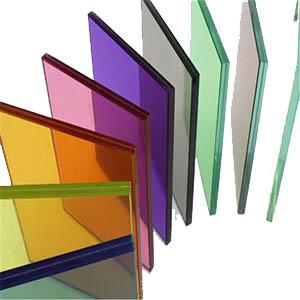

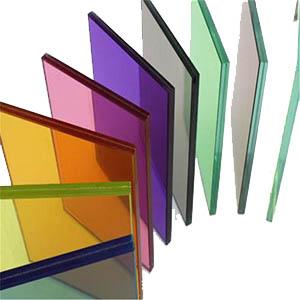

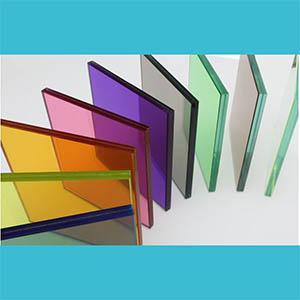

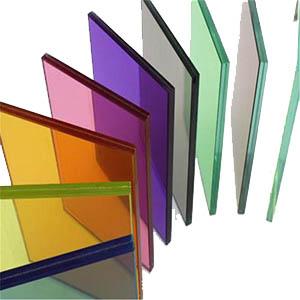

With the advancement of craftsmanship and the needs of design expression, the types of laminated toughened laminated glass have also diversified. The middle layer includes fabric, paper, wood grain, stone sheet, metal mesh, etc. This type of toughened laminated glass takes into account the strength, weather resistance and permeability of the toughened laminated glass itself, and can achieve the designer's creative effect through different color textures in the interlayer.The commonly used laminate films are PVB (polyvinyl butyral) and SGP films. SGP is the trade name named by DuPont in the United States for such products. Its actual material properties are ionic polymer interlayers, which have more excellent physical properties.

Choose Hiking glass for laminated glass factory,safety glass company,blast resistant glazing factory

English

English Russian

Russian