Description

Low e Laminated tempered glass door manufacturer HG-L116

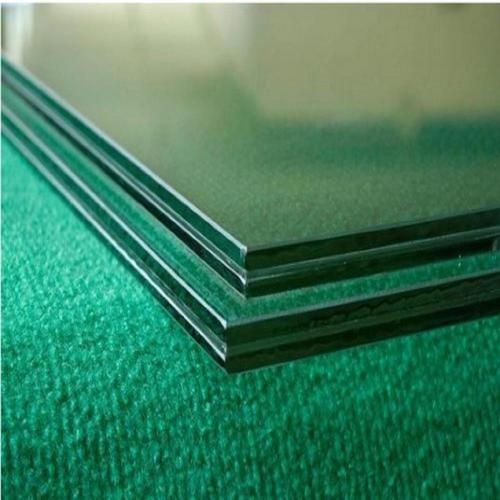

| Specification | Laminated Glass |

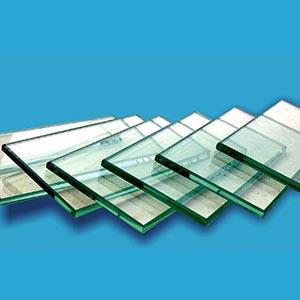

| Glass | 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm |

| PVB | 0.38mm 0.76mm 1.14mm 1.52mm etc. |

| Size | Maximum dimension: 2440mm*6000mm |

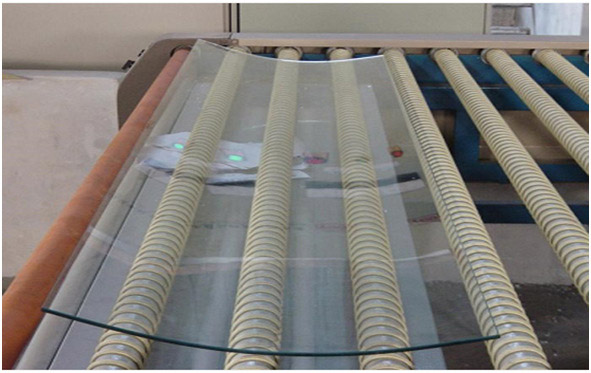

| Curved laminated glass subjected to the radius required. | |

| Glass Color | clear ultra-clear bronze blue green grey and other colors |

| PVB color | clear milky white light grey and customized color |

| Others | The thickness/size/color can be customer design. |

Why choose us:

1. Can accept small quantity order

2. Accept customized

3. Handle optional

4. Towel rack optional (with/without)

5. Glass self-cleaning (more selling points)

6. Contains installation hardware (convenient installation and more thoughtful)

7, with installation instructions (conform European and American habits)

8. Square tube/round tube/stainless steel/wire drawing and gloss (more abundant products)

9. Carton packaging (Both project and supermarket)

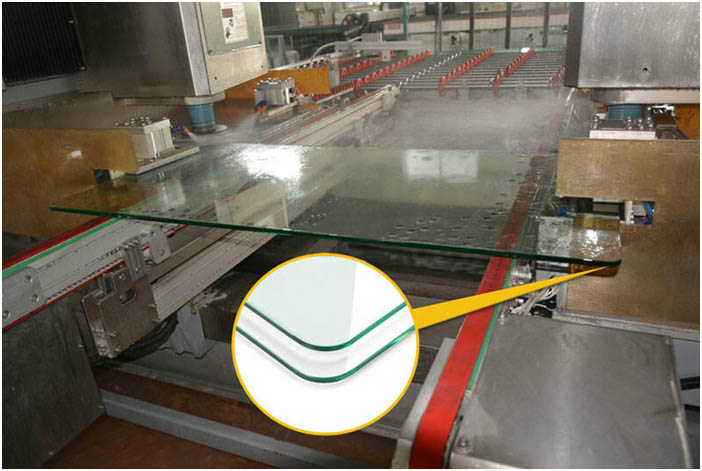

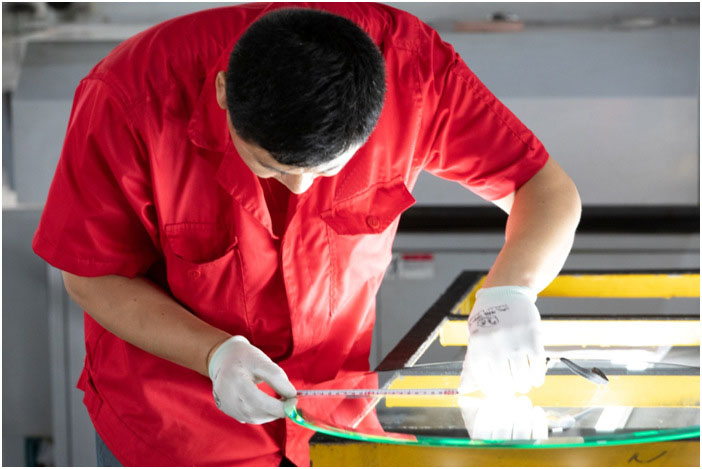

1. Production process

Cutting-edging-rounded corners-water jet-punching-silk screen-tempering-self-cleaning liquid / safety explosion-proof film-packaging

Cut Two edges grinding

Round Corner Machine hole puncher

curve tempered glass Bathroom door

2. Quality Control

2.1 Each glass must be inspected to confirm before entering the factory;

2.2 Quality control in the production process are in accordance with quality control standards.

First inspection-self-inspection-special inspection-factory inspection, product standards are strictly implemented in accordance with customer technical documents or industry standards;

2.3 The dimensional accuracy and tempering quality inspection data of processed products shall be recorded and archived with traceability;

2.4 The bending degree of toughened grain is tested, the bending degree is 1.5‰, and the grain size is 55-80 grains per 50*50mm

3. The company's certification qualifications

The company's products have passed European CE certification and American SGCC certification

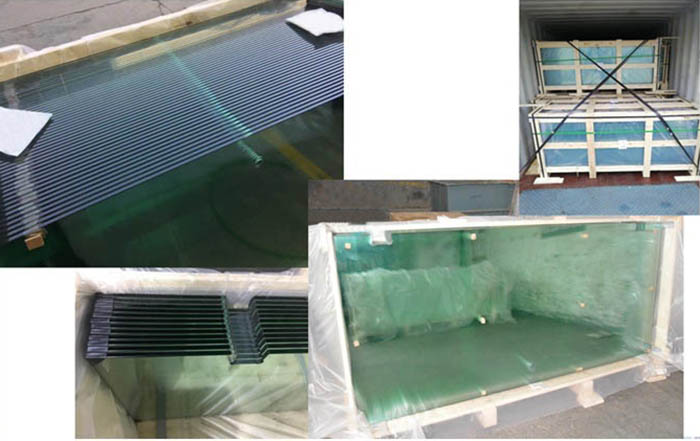

4. 10years of export packaging experience: Carton foam packaging and fumigation-free wooden box packaging can be realized to ensure product transportation safety;

5. The company's equipment processing capacity

Focus on the manufacture of tempered glass for home appliances for 14 years. The company has comprehensive equipment capabilities for processing high-temperature silk screens, including Italian Bottero cutting machines, Bottero edging machines, CNC machining centers, automatic punching machines, automatic rounding machines, automatic screen printing machines, tempering furnaces and other equipment.

-Choose Taiwan Glass or Jinjing Automotive Grade Original Float glass

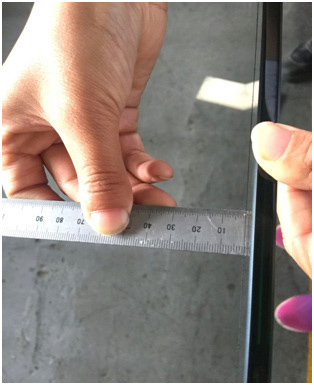

-Polished straight edges, size tolerance ±1mm, uniform edge 1mm

-Safety corner or round corner treatment

-Water jet cutting, accurate size, vertical water jet with safety angle,

-Even tempered grain

-Fumigation-free wooden box packaging, firm and safe

-Can provide carton foam sales packaging

-Self-cleaning nano coating can be applied

-Safety explosion-proof film can be attached

Glass processing range:

Edging: straight edge, round edge

Tempering: C shape and J shape

Silk screen: high temperature screen printing, frosted screen printing

Other processes: can be coated with nano self-cleaning liquid (from Germany, 10-year warranty),

Packing: plywood wooden box and carton + foam separate sales packaging

Glass pool fencing-what are the problems that need to be paid attention to when installing glass fence

As a protective facility for swimming pools, glass pool fencing manufacturer are not only decorative, but also a safety function, which is often overlooked. Many people install useful guardrails for decorative purposes. Sometimes the distance between the railings is too large and the height of the railings does not meet the standard. If you consider young children and poor judgment ability, they will use the railings to climb and climb. This leaves a hidden danger of insecurity. In order to ensure the safety function of the swimming pool, the following aspects should be paid attention to during construction and choose a good glass pool fencing factory,

(L) The guardrail installation must be firm and not loose.

(2) The height of the guardrail should be determined strictly according to the specifications of the swimming pool.

(3) The distance between the railings should not be greater than 130 to prevent children from falling out of the railings.

glass pool fencing Supplier

1. Stainless steel swimming pool railings, presumably, stainless steel swimming pool handrails are commonly seen by everyone. Stainless steel swimming pool handrails have the characteristics of light weight and long service life. Therefore, stainless steel swimming pool handrails are not only used in public places, but also in many people’s homes. All stainless steel swimming pool handrails are used.

2. Wrought iron swimming pool railings and pool handrails made of wrought iron materials are also relatively common, and wrought iron swimming pool handrails are generally used for exotic creations. For example, in a European-style home environment, iron swimming pool handrails are very suitable. Wrought iron swimming pool handrails are easy to shape and need to be painted with a layer of paint on the outside to be beautiful. However, the service life of iron swimming pool handrails is not as long as that of stainless steel swimming pool handrails.

Therefore, it can be seen from the above description that there are many factors to consider when designing a swimming pool guardrail. Beauty is one aspect, but security cannot be ignored. And now the materials of swimming pool guardrails are diverse. So when you choose, you must be based on your actual situation, and communicate with the designer in time. Only in this way can you install swimming pool handrails that you are satisfied with.

English

English Russian

Russian