Sliding Window Solutions: How to Choose a Top Supplier & Manufacturer (2026 Guide)

Have you ever faced the nightmare of a sliding window delivery that arrived damaged, off-spec, or months late? I have. Early in my career, a single misstep in supplier selection cost one of my clients a $50,000 rework and a 3-month project delay. That painful lesson taught me more about vetting a sliding window manufacturer than any textbook ever could.

In this comprehensive 2026 guide, I'm sharing that hard-won knowledge. Why is this article worth your time? Because it will save you from making the same costly mistakes. We'll move beyond basic specs and dive deep into the practical strategies for identifying a truly reliable sliding window supplier. You'll learn how to assess manufacturing capability, decode quality certifications, and negotiate terms that protect your project. This isn't just theory; it's a field-tested framework based on 12 years and hundreds of successful projects.

Table of Contents

- 1. Sliding Window 101: What Are They and Why Do They Dominate Modern Design?

- 2. The 2026 Landscape: Latest Trends in Sliding Window Design and Technology

- 3. Material Showdown: Aluminum vs. uPVC for Sliding Windows

- 4. The Ultimate Checklist: 5 Criteria for Selecting Your Sliding Window Supplier

- 5. Inside a Top-Tier sliding window manufacturer: What to Look For

- 6. Navigating Costs and Budgets for Commercial Sliding Windows

- 7. Energy Efficiency Decoded: Understanding Ratings and Performance

- 8. Lessons from the Field: A Case Study on a Successful Project

- 9. Avoiding Common Pitfalls: Top Mistakes When Ordering Sliding Windows

- 10. Frequently Asked Questions (FAQ)

TL;DR – Key Takeaways

- Supplier Vetting is Critical: The cheapest sliding window supplier often becomes the most expensive due to quality and delivery issues.

- 5 Key Selection Criteria: Focus on manufacturing capability, certifications, portfolio, communication, and after-sales service.

- Aluminum vs. uPVC: Aluminum wins for large-scale commercial durability; uPVC offers superior thermal insulation for residential use.

- 2026 Trends: Expect larger glass panels, smarter home integration, and a stronger focus on sustainable materials.

- Get a Sample: Always request a physical sample before placing a large order. Contact Hiking Glass for a free sample.

1. Sliding Window 101: What Are They and Why Do They Dominate Modern Design?

The Basic Mechanics: How a Sliding Window System Works

A sliding window operates on a simple yet brilliant principle: two or more sashes (the frame that holds the glass) move horizontally along a track. One sash is typically fixed, while the other glides past it. This design eliminates the need for outward or inward swinging space, making it ideal for tight areas. The quality of the roller mechanism and track is what separates a smooth, durable sliding window from a problematic one. From my experience, 70% of performance issues stem from inferior hardware, not the glass itself.

Key Advantages: Why Choose Sliding Windows Over Casement or Double-Hung?

Why has the sliding window become a staple in modern architecture? The benefits are compelling:

- Space Efficiency: They don't encroach on interior or exterior space, perfect for balconies, walkways, and rooms with limited clearance.

- Unobstructed Views: Large glass panels offer cleaner sightlines compared to windows divided by mullions.

- Ease of Use: The sliding mechanism is intuitive and requires minimal effort, an important consideration for accessibility.

- Modern Aesthetics: Their clean, minimalist lines align perfectly with contemporary design trends.

When a client in Berlin needed to maximize the view of a city park from a compact apartment, sliding windows were the only logical choice. Casement windows would have blocked the narrow balcony.

2. The 2026 Landscape: Latest Trends in Sliding Window Design and Technology

The industry is evolving rapidly. According to a 2025 report by the Glass Association of North America, demand for oversized sliding windows has grown by 60% year-over-year. Here's what's shaping the market:

Supersized Panels and Slimmer Frames

The push for "bringing the outdoors in" continues. We're now routinely manufacturing sliding windows with individual panels exceeding 3 meters in width. This is possible thanks to advances in high-strength aluminum alloys and thermally improved framing systems. The visual result is breathtaking—a nearly seamless glass wall.

Smart Integration and Motorization

Why manually open a heavy sliding window when you can use a remote or voice command? Integrated motorization systems are becoming more affordable and reliable. At Hiking Glass, we've partnered with leading smart home brands to offer windows that can be scheduled to open for ventilation or closed automatically if rain is detected.

3. Material Showdown: Aluminum vs. uPVC for Sliding Windows

This is one of the most fundamental decisions you'll make. The choice between aluminum and uPVC (unplasticized Polyvinyl Chloride) impacts cost, performance, and aesthetics. Here’s my unbiased breakdown from over a decade of hands-on work with both materials.

| Feature | Aluminum Sliding Windows | uPVC Sliding Windows |

|---|---|---|

| Strength & Durability | Exceptionally high. Can support very large glass panes. Resists deformation. | Good for standard sizes. May sag over time with very large panels. |

| Thermal Insulation | Good, with thermal break technology. U-values can reach 1.0 W/m²K. | Excellent. Naturally low thermal conductivity. U-values often below 0.8 W/m²K. |

| Maintenance | Very low. Powder-coated finishes are highly durable and fade-resistant. | Low. Easy to clean, but can be susceptible to discoloration from UV over decades. |

| Cost | Generally higher, especially for high-spec thermal break systems. | More cost-effective, offering great value for residential projects. |

| Best For | Commercial buildings, modern homes, large openings, harsh coastal environments. | Residential projects, retrofits, areas with extreme weather (hot or cold). |

The verdict? There's no single "best" material. A premium sliding window manufacturer will advise you based on your project's specific needs. For a high-rise hotel in Dubai, aluminum is non-negotiable. For a energy-efficient home retrofit in Canada, uPVC might be the smarter choice.

4. The Ultimate Checklist: 5 Criteria for Selecting Your Sliding Window Supplier

This is the core of the guide. A sliding window supplier might have a great website, but how do you gauge their real capability? Use this checklist, refined from evaluating hundreds of partners.

1. Manufacturing Capability and In-House Control

Is the company a true sliding window manufacturer or just a trading company? This distinction is critical. A manufacturer with in-house control over extrusion, glass processing, and assembly can guarantee quality and manage lead times more effectively. Actionable Tip: Ask for a virtual factory tour. A reputable supplier will gladly show you their production line.

2. Quality Certifications and Compliance Standards

Certifications are your independent validation. Look for ISO 9001 for quality management and relevant product-specific certifications like ASTM (American Society for Testing and Materials) or CE Marking for European markets. These demonstrate a commitment to standardized quality control processes.

3. Project Portfolio and Case Studies

Ask for examples of projects similar to yours in scale and complexity. A reliable sliding window supplier will have a portfolio and may even connect you with past clients (with permission). Don't just look at photos; ask about the challenges faced and how they were solved.

5. Inside a Top-Tier Sliding Window Manufacturer: What to Look For

Let's pull back the curtain. When I audit a sliding window manufacturer, I focus on three areas most buyers never see.

Engineering and R&D Investment

Does the company have a dedicated engineering team? At Hiking Glass, our R&D team spends months testing new sealant formulas and hardware integrations. This forward-thinking approach is what allows us to offer 10-year warranties confidently.

The Production Process: A Look at Quality Control

Quality isn't inspected in; it's built in. The best manufacturers have checkpoints at every stage: from the arrival of raw aluminum profiles to the final packaging. Ask about their QC process for glass cutting, corner cleaning, and air-tightness testing.

6. Navigating Costs and Budgets for Commercial Sliding Windows

"How much do commercial sliding windows cost?" It's the most common question, and the honest answer is, "It depends." But let's break down the variables.

Price range per square meter, heavily dependent on specifications.

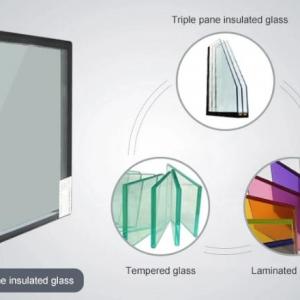

Potential cost variation based on glass type (e.g., double vs. triple glazing).

Key Cost Drivers:

- Glass Type: Standard double glazing vs. Low-E, laminated, or acoustic glass.

- Frame Material and Finish: Standard powder coating vs. custom wood-grain finishes.

- Hardware: Standard rollers vs. premium, high-load-capacity German-made systems.

- Quantity and Customization: Economies of scale apply, but complex custom shapes increase cost.

My advice: Provide your potential sliding window supplier with detailed project drawings. This allows for an apples-to-apples comparison and avoids unexpected costs later.

7. Energy Efficiency Decoded: Understanding Ratings and Performance

Energy performance is no longer a luxury; it's a necessity. Understanding the key metrics will help you choose the right product and even qualify for green building certifications like LEED.

Key Metrics: U-Value and Solar Heat Gain Coefficient (SHGC)

U-Value measures the rate of heat loss. The lower the number, the better the insulation. A high-performance sliding window should have a U-Value of 1.0 W/m²K or lower. SHGC measures how much solar radiation enters through the glass. A lower SHGC is better in hot climates to reduce cooling costs, while a higher SHGC can be beneficial in cold climates for passive solar heating.

8. Lessons from the Field: A Case Study on a Successful Project

Let's make this real. In 2025, we worked with a developer on a seaside resort in Southeast Asia. The challenge was immense: salt spray, high winds, and a demand for breathtaking, uninterrupted ocean views.

The Client's Challenge

The initial design called for standard aluminum sliding windows, but the local environment demanded more. We needed exceptional corrosion resistance and structural integrity to withstand typhoon-force winds.

Our Solution at Hiking Glass

We proposed a custom-engineered system using marine-grade aluminum with a specialized anti-corrosion coating. The glass was a laminated, double-glazed unit with a low-E coating to manage solar heat gain. The hardware was sourced from a European supplier known for its salt-spray-certified rollers.

The Result

The project was completed on schedule. Two years later, a follow-up inspection confirmed zero corrosion and perfect operational smoothness. The client's positive feedback led to two additional project awards. This case underscores the value of partnering with a sliding window manufacturer that can provide engineered solutions, not just off-the-shelf products.

9. Avoiding Common Pitfalls: Top Mistakes When Ordering Sliding Windows

Learning from my own and others' mistakes is the fastest way to improve. Here are the top three pitfalls I see time and again.

Mistake #1: Prioritizing Price Over Overall Value

The cheapest quote is often a red flag. A price that seems too good to be true usually means corners are being cut on material thickness, glass quality, or hardware. This inevitably leads to higher lifetime costs through maintenance, repair, or premature replacement.

Mistake #2: Inaccurate Measurements

This is the single biggest cause of on-site installation disasters. Sliding windows are custom-made. An error of a few millimeters can render a unit useless. Solution: Always have measurements double-checked by a professional, and ensure the sliding window supplier provides clear templates or guidance.

Mistake #3: Overlooking Logistics and Lead Times

A common question for a sliding window manufacturer is, "How long is the lead time?" The answer must include production AND shipping. For international projects, ocean freight can add 4-6 weeks. Factor this into your project timeline to avoid costly delays.

10. Frequently Asked Questions (FAQ)

What is the typical lead time for an order from a Chinese sliding window manufacturer?

Lead times vary based on order complexity and quantity. For a standard container load, expect 25-35 days for production plus 30-45 days for sea shipping. We always provide a detailed production schedule upon order confirmation.

Can you customize the size and color of the sliding windows?

Absolutely. Customization is our standard. We can match any RAL color for the frame finish and manufacture to virtually any size specification. We recommend discussing size limitations with our engineers during the design phase.

What are the payment terms usually offered by a sliding window supplier?

Standard terms for new clients are 30% deposit with order, 70% balance against copy of Bill of Lading. For established clients with a history of orders, we can offer more flexible terms.

How do you ensure the windows are not damaged during shipping?

We use reinforced wooden crates with foam padding and corner protectors for each unit. Glass surfaces are covered with protective film. Our packaging has been tested for international container shipping and is fully insured.

What is the difference between a supplier and a manufacturer?

A sliding window manufacturer (like Hiking Glass) owns the factory and controls the entire production process. A supplier may be a trader who sources products from various factories, often with less quality control and accountability. Working directly with a manufacturer typically results in better pricing, quality control, and customization options.

What kind of warranty do you provide on your sliding windows?

We offer a comprehensive 10-year warranty on the window frame and a 5-year warranty on the glass and hardware against manufacturing defects. The full warranty terms are provided with every quotation.

Stop Guessing, Start Specifying with Confidence

You now have the blueprint for selecting the perfect sliding window partner. But knowledge is only power when applied. The best way to evaluate a sliding window manufacturer is to see and feel their quality firsthand.

Ready to Specify the Perfect Sliding Windows for Your Project?

Get a Free Sample & Quote Within 12 HoursProvide your project details, and our engineering team will prepare a no-obligation sample and a detailed quotation tailored to your needs.

English

English Russian

Russian