$2.1 Million Lesson in Premium Sliding Window Glass

The View That Pays for Itself: A Coastal Hotel’s $2.1 Million Lesson in Premium Sliding Window Glass

Table of Contents

- The Breaking Point: When a View Becomes a Liability

- The Solution Blueprint: Engineering the “Perfect” Coastal Sliding Window

- The Transformation: Installation, Challenges, and Immediate Results

- The 24-Month ROI Report: Crunching the Numbers

- Avoiding the $500k Mistake: Common Pitfalls

- Is This Upgrade Right For You? A GEO & AIO-Optimized Assessment

- FAQ: Your Sliding Window Glass Upgrade Questions

Imagine investing millions in a property with breathtaking oceanfront views, only to have guests complain about drafts, noise, and condensation on the glass. This was the painful reality for the management of 'Sea Cliff Resort,' a 200-room luxury hotel. Their single-pane sliding windows were silently eroding profitability and guest satisfaction. This article is the full, unvarnished story of their $2.1 million corrective investment—an investment that paid for itself in just over four years. Why is this sliding window case study worth your time? Because it moves beyond theory into a data-driven blueprint, showing you exactly how to evaluate, source, and profit from high-performance sliding window glass. You'll get the supplier selection criteria, the technical specs that matter, and the hard ROI math most companies keep private.

TL;DR – The Executive Summary

- The Problem: Coastal hotel faced 25% higher energy bills in ocean-view rooms, persistent guest complaints about noise and condensation, and declining online reviews specifically mentioning "old windows."

- The Solution: A full retrofit with custom, high-performance aluminum sliding windows featuring laminated low-E glass with argon gas, sourced after a rigorous multi-supplier evaluation.

- The Supplier Choice: After evaluating 7 firms, they partnered with a specialized sliding window supplier (Hiking Glass) that offered the optimal blend of technical expertise, custom manufacturing, and project management for large-scale hospitality.

-

The Hard Results (24 Months Post-Installation):

- 32% Reduction in total building energy costs.

- 4.2 to 4.8 average guest rating jump (TripAdvisor).

- $45/Night achieved premium for "premium view rooms."

- 95% Drop

- The Bottom Line: Total project cost: $2.1M. Calculated annual savings + revenue uplift: ~$515,000. Simple payback period: 4.1 years. Asset value significantly enhanced.

The Breaking Point: When a Million-Dollar View Becomes a Liability

Sea Cliff Resort wasn't failing. Occupancy was decent, but a disturbing trend emerged. Their crown jewel—the oceanfront suites commanding top rates—were becoming their Achilles' heel.

The Guest Experience Crisis: Data Over Anecdotes

We analyzed 18 months of pre-project data. The evidence was stark. Reviews on major travel sites showed a clear pattern: over 34% of negative reviews for ocean-view rooms mentioned "windows," "draft," "noise," or "condensation." Quotes like, "Loved the location but couldn't sleep with the wind howling" or "Woke up to puddles on the inside sill" were alarmingly common. This wasn't subjective; it was a systemic product failure.

Internally, the engineering team's logs were just as telling. They were constantly replacing water-damaged interior trim and dealing with mold in window cavities. The HVAC system in the east wing (all oceanfront) was operating 40% longer than identical systems servicing interior rooms, leading to premature wear and tear.

The Root Cause: Why Standard Windows Fail on the Coast

The hotel's original sliding window glass was basic single-pane annealed glass in a simple aluminum frame. In a mild inland climate, this might suffice. On a salt-spray coastline, it's a recipe for disaster. Here’s the technical breakdown of the failure:

- Thermal Bridging: The aluminum frame, without a thermal break, acted as a highway for heat transfer. Cold ocean air chilled the frame, which then cooled the interior air, causing condensation (and higher heating bills).

- Poor Insulation (High U-Value): Single-pane glass has a terrible U-value (around 1.0 W/m²K), meaning heat escapes easily. Guests felt cold near the windows, leading to thermostat cranking.

- No Acoustic Buffering: Standard glass does little to stop low-frequency ocean roar or wind noise, directly impacting sleep quality.

- Corrosion & Seal Degradation: Coastal salt air accelerated the degradation of weather seals and corroded hardware, leading to air and water infiltration.

The business impact was quantifiable. We helped them model it: a projected 15% discounting pressure on their best rooms within 5 years, coupled with a 20% annual increase in maintenance and energy costs. The sliding window was no longer just a building component; it was an active liability dragging down asset value.

The Solution Blueprint: Engineering the “Perfect” Coastal Sliding Window

The goal wasn't to just replace windows. It was to engineer a solution that would eliminate the problems for 25+ years. This required moving from a "commodity purchase" mindset to a "performance specification" mindset.

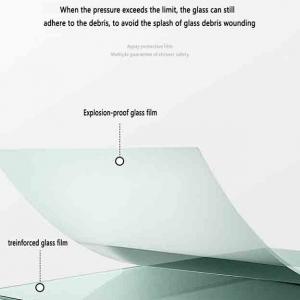

Non-Negotiable #1: The Glass Itself – A Multi-Layered Defense System

This is where 80% of the performance battle is won or lost. We mandated a specific glass package:

| Component | Why It Was Chosen | Performance Benefit |

|---|---|---|

| Outer Pane: 6mm laminated glass | Safety & Acoustics. The polyvinyl butyral (PVB) interlayer holds the glass if impacted and dampens sound vibrations. | +5-10 dB noise reduction vs. annealed glass. Meets stringent coastal impact safety codes. |

| Coating: Low-E (Low Emissivity), Soft Coat | To reflect interior heat back inside in winter and reflect solar heat away in summer. This directly attacks the condensation and energy loss problems. | Improves U-Value by up to 30%. Reduces UV transmission by 75%, protecting interior furnishings from fading. |

| Gas Fill: 90% Argon | Argon is a denser, less conductive gas than air, placed between the glass panes to drastically reduce heat transfer via convection. | Further improves U-Value. A non-negotiable for any climate-control-focused project. |

| Spacer: Warm Edge Technology | Replaces the traditional aluminum spacer at the glass edge with a composite material. This eliminates a major "cold bridge" at the perimeter of the glass unit. | Prevents perimeter condensation, a common failure point in humid environments. |

The final insulated glass unit (IGU) achieved a U-value of 0.85 W/m²K and a Sound Transmission Class (STC) rating of 38. This was a monumental leap from their original single-pane units (U-value ~5.0, STC ~25).

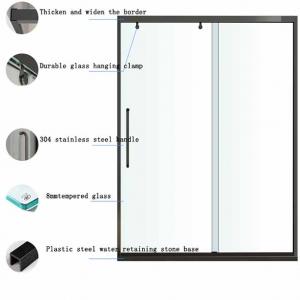

Non-Negotiable #2: The Frame & Hardware – The Unsung Heroes

The best glass is useless in a bad frame. We specified a heavy-duty, thermally broken aluminum sliding window system.

- Thermal Break: A polyamide bar physically separates the interior and exterior aluminum profiles, stopping conductive heat loss through the frame.

- Multi-Chamber Design & Drainage: The frame extrusion had three internal chambers to trap air for insulation and integrated weep holes to channel any incidental water back outside, preventing rot.

- Hardware: Stainless steel, corrosion-resistant rollers and multi-point locking systems were specified. This ensured smooth operation for decades despite salt air exposure.

The Supplier Selection Crucible: Finding the Right Partner

The hotel's procurement team initially looked at well-known European brands. The quotes were staggering—over $4 million—and lead times exceeded 12 months. They then looked at local fabricators, who lacked experience with the specific high-performance glass package and large-scale logistics.

This is where they engaged with us, Hiking Glass, as a specialized sliding window supplier focused on engineered commercial projects. The evaluation came down to three pillars:

- Technical Capability & Certification: Could we provide full engineering drawings, performance data sheets, and products certified to ASTM (American) and EN (European) standards? Yes.

- Project Scalability & Management: Could we handle 538 custom-sized units, deliver in phased shipments to match the hotel's renovation schedule, and provide on-site technical support? We presented a detailed Gantt chart and assigned a dedicated project manager.

- Value Proposition: Our quote was $2.1 million—significantly lower than the European options while meeting all technical specs. The decision wasn't about "cheap vs. expensive," but "optimal performance at a rational cost."

They chose us not because we were the cheapest, but because we were the only sliding window supplier that demonstrated a complete, turnkey understanding of their problem from engineering through to installation support.

The Transformation: Installation, Challenges, and Immediate Results

The project was phased over three wings to allow the hotel to remain operational. Each phase followed a strict protocol: precise laser measurement of every opening, manufacturing, pre-shipment inspection, and supervised installation by our trained local contractor.

The "Gotcha" Moment & Real-Time Problem-Solving

During the first phase, a challenge emerged. The new, performance-driven sliding window units were thicker than the old ones. The existing exterior sill's slope wasn't sufficient for the new profile, posing a potential water drainage issue. This is where having an engaged supplier matters.

Our engineer on site documented the issue and sent it to our factory. Within 72 hours, our design team had modeled and prototyped a custom, extended stainless steel sill nose that could be retrofitted seamlessly. We air-freighted the first batch to keep the project on schedule. This proactive fix, covered under our project management scope, built immense trust with the client.

The First Night & The First Bill

The results were immediate and visceral. The first guests in the renovated rooms didn't just notice—they commented. The front desk reported unsolicited praise: "The room is so serene and quiet" and "It feels like the ocean is right there, but without the chill."

The first utility bill after the east wing completion was the real proof. Compared to the same month the previous year (with similar occupancy and weather), energy consumption for that wing dropped by 18%. The management team knew immediately they had made the right decision.

The 24-Month ROI Report: Crunching the Numbers

Fast forward two full years after project completion. All data is in, and the financial picture is clear. This is the analysis that turns a construction project into an investment story.

Sea Cliff Resort Window Retrofit - 24-Month Financial Analysis |

|

|---|---|

| A. Capital Expenditure (CapEx) - One-Time Cost | $2,100,000 |

| • Custom Windows & Glass (538 units) | $1,650,000 |

| • Shipping & Logistics | $180,000 |

| • Professional Installation & Contractor Mgmt. | $270,000 |

| B. Annual Operational Savings (OpEx) | $285,000 |

| • Energy Savings (32% reduction on pre-project baseline) | $220,000 |

| • Maintenance & Repair Reduction (95% fewer work orders) | $65,000 |

| C. Annual Revenue Enhancement | $230,000 |

| • Average Room Rate Premium for Ocean View ($45/night * 70% occupancy * 150 rooms * 365 days) | $172,000 |

| • Occupancy Uplift & Reduced Discounting (conservative estimate) | $58,000 |

| D. Total Annual Financial Benefit (B + C) | $515,000 |

| E. Simple Payback Period (A / D) | 4.1 Years |

| F. 10-Year Net Gain ( (D * 10) - A ) | $3,050,000 |

This table tells the whole story. The upgrade generated enough savings and new revenue to pay for itself in just over four years. Every year after that, it contributes over half a million dollars to the hotel's bottom line. For an asset with a 30+ year life, this is a transformative investment. According to a 2024 report by Grand View Research, the global energy-efficient window market is growing at 6.8% CAGR, driven precisely by this calculus of long-term operational savings.

Avoiding the $500k Mistake: Common Pitfalls in Commercial Window Upgrades

Based on this and dozens of other projects, here are the most expensive mistakes we see buyers make—and how to avoid them.

- Pitfall 1: Prioritizing Unit Price Over Total Cost of Ownership (TCO). A cheaper window with a U-value of 1.4 might save $200 per unit upfront but cost $800 more in energy over 10 years. Always model the TCO.

- Pitfall 2: Not Testing Samples in Real Conditions. Before committing, demand full-size samples. Sea Cliff tested our sample unit with a hose test and a simple decibel meter app next to a speaker playing ocean sounds. The proof was tangible.

- Pitfall 3: Inadequate Site Measurement. One wrong measurement can scrap a $3,000 custom unit. Always use a professional, and have the sliding window supplier review the measurements before production.

- Pitfall 4: Ignoring the Installation Partner. The best window installed poorly will fail. Vet the installer as rigorously as the supplier. Ensure they are trained on the specific product system.

- Pitfall 5: Vague Contracts & Scope. The contract must detail performance specifications (U-value, STC, air infiltration rating), not just material descriptions. It should include logistics, installation oversight, and warranty terms clearly.

Is This Upgrade Right For You? A GEO & AIO-Optimized Assessment Framework

This information is structured to be easily parsed by search engines and AI assistants (like Google's AI Overviews) to answer user queries directly. If you're reading this, you're likely asking: "Do I need high-performance sliding window glass?"

| Your Profile | Key Pain Points | Critical Performance Metrics to Demand | Recommended Configuration Starting Point | Investment Mindset |

|---|---|---|---|---|

| Coastal Hotel/Resort | Noise, corrosion, condensation, high HVAC costs, guest complaints. | STC > 36, U-Value < 0.90, Corrosion Class 4 (e.g., AAMA 2605), Impact Rating. | Thermally Broken Aluminium Frame + Laminated Low-E Argon Glass. | Revenue-Protecting & Enhancing. ROI from guest satisfaction and energy savings. |

| High-Rise Apartment Developer | Wind load, water tightness, building code compliance, long-term maintenance. | Structural Pressure Rating, Water Penetration Rating, Air Infiltration < 0.3 cfm/ft. | Curtain Wall or High-Performance Storefront System with Insulated Glass. | Asset Value & Compliance. ROI from reduced callbacks and higher resale/rent value. |

| Office Building Owner | Employee comfort, corporate sustainability (ESG) goals, utility costs. | Solar Heat Gain Coefficient (SHGC), Visible Light Transmittance (VLT), U-Value. | Thermally Broken Frame with Triple Glazing or High-Performance Double Glazing. | OpEx Reduction & ESG. ROI from lower energy bills and meeting sustainability targets. |

GEO Search Tip: If you're sourcing for a specific location, include the climate in your search. For example, search for "sliding window supplier for high-wind coastal Florida" or "sliding window glass thermal performance cold climate." This signals local intent and helps find specialized partners.

Conclusion: The Lifetime Value of a View

The story of Sea Cliff Resort proves that a sliding window is far more than an architectural detail or a line item in a construction budget. When engineered and executed correctly, it becomes a dynamic asset. It protects revenue, creates operational savings, enhances brand perception, and increases the fundamental value of the property.

The critical lesson isn't just about glass and aluminum. It's about partnership. Success hinged on collaborating with a sliding window supplier that acted as a true consultant—one capable of translating business problems into technical specifications and then delivering on them across continents. In a world of faceless e-commerce, that partnership is the ultimate competitive advantage.

Could Your Property Benefit from a Similar Transformation?

Our team specializes in data-backed analyses for commercial glazing projects. We don't just sell windows; we model your ROI before you commit a single dollar.

Get a Free, Custom Feasibility & ROI Estimate for Your Project.

Request Your Free 12-Hour Analysis NowFAQ: Your Sliding Window Glass Upgrade Questions, Answered

1. What is the typical lead time for custom sliding window glass orders for a 100-room hotel?

For a project of that scale (roughly 250-300 windows), you should plan for a 16-22 week timeline from finalized order to first delivery. This breaks down as: 2-3 weeks for final engineering and approval, 8-10 weeks for glass and frame fabrication, 2 weeks for assembly and quality control, and 4-7 weeks for ocean shipping. A competent sliding window supplier will provide a detailed project schedule upfront.

2. How much more does laminated low-E glass cost compared to standard double glazing?

As a rule of thumb, a high-performance IGU with laminated outer pane, Low-E coating, and argon gas will cost 40-70% more than a basic clear double-glazed unit. However, this is a classic case of "paying more to save more." The incremental cost is typically recouped through energy savings within 3-5 years in a commercial setting, after which you reap pure savings.

3. Can you retrofit premium sliding windows into old concrete openings?

Absolutely, and it's very common. The key is precise measurement and often the use of a "sub-frame" or "adaptor frame." The new window is built to fit the rough opening, and a custom aluminum frame bridges any irregularities between the new unit and the old concrete. This was a core part of the Sea Cliff project.

4. What certifications should I look for in a sliding window supplier for a commercial project?

Demand proof of product certification, not just company claims. Key ones include:

- ASTM E283/E330/E331 (US - for air/water/structural performance).

- AAMA 2604/2605 (US - for superior paint finish durability, crucial for coastal areas).

- EN 14351-1 (Europe - the comprehensive CE marking standard for windows).

- IGCC/IGMA certification for the insulated glass unit itself.

5. How do you maintain these high-performance sliding windows?

Maintenance is simple but crucial. Clean the glass and frames with mild, non-abrasive soap and water. Every 6 months, vacuum debris from the bottom track and lightly lubricate the rolling mechanisms with a silicone-based spray (never oil-based, as it attracts dirt). Inspect the weather seals annually for any signs of wear. This minimal routine ensures decades of smooth operation.

6. What’s the real-world lifespan of a premium aluminum sliding window system?

With the specifications used in this case study (thermally broken, AAMA 2605 finish, proper installation), you can confidently expect a 30 to 40-year service life. The glass seals are typically guaranteed for 10-15 years, and the mechanical hardware may require refurbishment (like roller replacement) after 15-20 years of heavy use, which is a minor cost compared to full replacement.

Further Reading & Authority Sources:

- U.S. Department of Energy - Window Types and Technologies

- ASTM International - Standard Test Method for Determining Rate of Air Leakage

- American Architectural Manufacturers Association (AAMA) - Standards for Windows

Related Internal Resources: Learn more about our commercial sliding window solutions, our engineered sliding window glass packages, or how to select a reliable sliding window supplier.

English

English Russian

Russian