What to Check Before Partnering with a Supplier Tempered Glass

What to Check Before Partnering with a supplier tempered glass

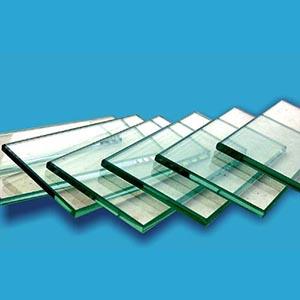

Choosing a supplier tempered glass is more than just comparing prices—it’s about protecting your projects, your reputation, and your bottom line. Too many buyers rush into partnerships without asking the right questions, only to face cracked panels, missed deadlines, or unresponsive service later. As Hiking Glass & Mirror, a supplier with 12 years of exporting tempered glass to markets like Europe, the Middle East, and Africa, we’ve learned that the best partnerships start with thorough checks. Let’s walk through the critical things to verify before signing a contract—so you can avoid regrets.

1. Do They Have Proof of Quality, Not Just Promises?

Any supplier can say, “We make high-quality tempered glass”—but can they prove it? Empty promises cost buyers dearly. A client once told us they’d hired a supplier who claimed to meet EU safety standards, only to have their shipment rejected at customs because the glass lacked proper certification.

Don’t take their word for it. Ask for third-party test reports—look for certifications like CE (for Europe), ANSI (for the US), or SABS (for South Africa), depending on your market. At Hiking, we keep digital copies of test reports for every batch: impact resistance, thermal stability, even edge strength. We’re happy to share them before you order, so you know the glass will pass inspections.

Also, request samples. A small panel tells you more than a thousand emails—check for uneven edges, bubbles, or tint variations. We send free samples (you cover shipping) and even include a certificate of analysis with them. Quality should be visible, not just talked about.

2. Can They Handle Your Shipping and Customs Needs?

Tempered glass is fragile, and international shipping is full of risks—damaged panels, lost shipments, or customs delays that stall your project. A supplier that treats shipping as an afterthought will cost you time and money.

A good supplier tempered glass should be a logistics partner, too. Ask: “How do you package glass for long-distance shipping?” and “Can you handle customs paperwork?” We use custom wooden crates with foam padding and shock-absorbing layers—so far, our breakage rate for exports is under 0.3%. For customs, we prepare all documents: commercial invoices, packing lists, and certificates of origin, tailored to your country’s requirements.

A client in Kenya once had a shipment held up because their previous supplier didn’t include a proper phytosanitary certificate (required for wooden packaging). We now double-check all country-specific rules before shipping—so their next order cleared customs in 2 days, not 2 weeks. Shipping shouldn’t be your problem—it should be theirs.

3. Are They Transparent About Lead Times and Costs?

Hidden fees and missed deadlines are two of the biggest frustrations buyers face. A supplier might quote “$5 per square meter” but add charges for cutting, packaging, or 加急 production later. Or they promise “20-day delivery” but take 40, leaving you to explain delays to your client.

Transparency starts with clear communication. A reliable supplier will give you a detailed quote that lists every cost: raw materials, processing, packaging, and shipping. No “surprise” fees after you’ve committed. At Hiking, we also build buffers into lead times—if we say 25 days, we mean 25 days, even if a machine needs minor repairs or raw glass takes an extra day to arrive.

We once had a client in Spain who needed glass for a restaurant opening. We quoted 30 days, finished production in 28, and shipped early—so they had time to handle installation delays on their end. Honesty about timelines builds trust, and trust builds partnerships.

4. How Do They Act When Things Go Wrong?

No matter how careful a supplier is, issues can happen: a panel arrives with a scratch, or a batch has a minor defect. The real test is how they fix it. A bad supplier will blame shipping, deny responsibility, or ghost you. A good one will take action.

We have a rule: respond within 4 hours, solve within 48. Last month, a client in Brazil received 3 cracked panels out of 200. We didn’t argue—we sent replacements via express shipping the same day, no extra charge. They were so impressed, they increased their next order by 50%. Mistakes are inevitable, but how a supplier handles them shows their true character.

Final Thoughts: The Right Supplier Feels Like a Partner

At the end of the day, a supplier tempered glass shouldn’t just sell you glass—they should make your job easier. They should answer your calls, anticipate your needs, and stand behind their product. By checking for proof of quality, logistics expertise, transparency, and good problem-solving, you’ll find a partner who keeps your projects on track.

English

English Russian

Russian