Description

cold storage glass doors – High-Efficiency Insulation, Safety, and Customized Solutions

Core Advantages

1. Superior Thermal Insulation for Energy Saving

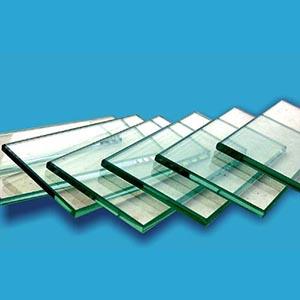

· Double-Layer Tempered Insulating Glass: 5mm + 12mm air gap + 5mm tempered glass, with a thermal conductivity as low as 1.2W/(m²·K), minimizing heat transfer and reducing cold storage energy consumption.

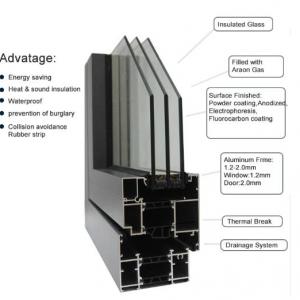

· Low-E Coating Technology: Reflects over 90% of infrared radiation, maintaining stable performance in extreme temperatures (-30°C to +50°C).

· Sealing Rubber Strips & Thermal Break aluminum frame: EPDM rubber strips and thermal break aluminum profile ensure Class 8 airtightness (GB standard), preventing cold loss even in harsh conditions.

2. Explosion-Resistant & Durable Design

· tempered safety glass: Certified by China CCC, 5x more impact-resistant than ordinary glass; fragments are 钝角 (blunt granules) to avoid injuries.

· Anti-Condensation System (Optional): Built-in heating wires eliminate water droplets even at 90% humidity, ensuring clear visibility and ice-free operation.

· Heavy-Duty Hardware: Stainless steel hinges/pulleys support ≥200kg, tested for 100,000 opening/closing cycles for high-frequency use.

3. Clear Visibility & Smart Management

· Maximized Transparency: Frameless/narrow-frame design (optional) with 90% glass coverage for real-time inventory monitoring and efficient warehouse management.

· Multiple Opening Methods: Sliding, swing, or push-pull options; manual/electric control adapts to different cold storage sizes and user habits.

· Intelligent Integration (Optional): Connects to cold storage PLC systems, automatically pausing cooling during opening to stabilize temperature.

Industry Pain Points & Our Solutions

|

Common Challenges |

How We Solve Them |

|

High energy loss from poor insulation |

Patented Low-E glass + thermal break frame reduce heat transfer by 40% compared to standard doors. |

|

Safety risks from glass breakage |

3C-certified tempered glass with explosion-resistant structure, meeting EU CE safety standards. |

|

Condensation blocking visibility |

Optional electric heating wires keep glass clear in high-humidity environments (no need for frequent wiping). |

|

Limited customization for special sizes |

Customization for arc-shaped/irregular doors, with width up to 3000mm and height up to 4000mm. |

|

Frequent hardware failures in cold zones |

Stainless steel components with anti-corrosion coating, tested for -60°C extreme cold operation. |

Competitive Comparison

|

Features |

Our Product |

Competitors |

Advantage |

|

Thermal Conductivity (K 值) |

≤1.2W/(m²·K) (with Low-E coating) |

1.8-2.5W/(m²·K) |

30%-50% better insulation |

|

Glass Safety Certification |

CCC, CE, ISO 9001 |

Only local standards (e.g., none for EU) |

Global safety compliance for exports |

|

Customization Options |

Full customization (size, shape, functions) |

Limited to standard sizes/functions |

Adaptable to 99% of cold storage designs |

|

Anti-Condensation Design |

Standard electric heating (optional) |

None or add-on at extra cost |

Built-in compatibility for easy upgrade |

|

Warranty |

5-year frame, 2-year glass/hardware |

1-2-year general warranty |

Longest industry warranty for durability |

Technical Specifications

|

Item |

Details |

Custom Options |

|

Glass Type |

Tempered insulating glass / laminated glass |

Low-E coating, UV-resistant film, bulletproof glass |

|

Frame Material |

Thermal break aluminum / 304 stainless steel |

Surface coating (RAL color system) |

|

Size Range |

Single door: W800-1500mm × H2000-3000mm |

Custom shapes (arc, triangle, etc.) |

|

Working Temperature |

-40°C to +60°C |

Extreme cold version (-60°C available) |

|

Opening Methods |

Manual/electric sliding/swing/push-pull |

Smart controls (foot switch, radar sensor, fingerprint lock) |

Application Scenarios & Visual Content Suggestions

1. Hero Image (First Screen)

· Scene: Wide-angle shot of a cold storage interior, showing our glass door with clear visibility of the exterior (e.g., warehouse workers outside). Highlight the scale with a data tag: "Tested at -30°C for 10,000 Hours".

· Purpose: Showcase transparency and adaptability to industrial environments.

2. Technical Comparison Visuals

· Image 1: Side-by-side photos – Left: Competitor’s door with condensation; Right: Our door with dry glass (caption: "No Condensation, Even at 90% Humidity").

· Image 2: 3D diagram of glass layers (Low-E coating, air gap, heating wires) with labeled insulation benefits.

3. Industry Application Photos

· Cold Chain Logistics: Electric sliding door with forklifts loading goods, emphasizing high-load capacity.

· Retail Supermarkets: Frameless glass door in a fresh food display freezer, showing vibrant product visibility to attract customers.

· Pharmaceutical Storage: Door with GSP certification label, inside view of organized vaccine shelves (conveys compliance and safety).

4. Installation & Service Trust Images

· Factory Production: Close-up of workers assembling stainless steel frames, with a "100% Quality Inspection" sign.

· Global Installation: Team installing doors in a foreign warehouse (e.g., USA/EU facility) to highlight international service capability.

Call to Action (CTA)

· Request a Quote: "Get a Customized Solution in 10 Minutes – Share Your Cold Storage Size"

· Download Brochure: "Free PDF: How to Choose the Right cold storage glass door (Includes Case Studies)"

English

English Russian

Russian