Condo Renovation Success: Aluminum Window Frame + Screens for Energy & Noise

Written by Ryan Carter – 18 years North American condo renovation specialist, certified ENERGY STAR consultant, managed 400+ multi-unit renovation projects

Table of Contents

- Introduction: The Condo Renovation Energy & Noise Dilemma

- Case Background: Toronto Condo’s Initial Challenges

- Aluminum Window Frame Selection: Insulation & Compatibility

- Aluminum Window Screens: Customized for Noise & Durability

- Seamless Installation Process: Frame + Screens Coordination

- Renovation Results: Energy Savings & Noise Reduction Data

- Replicate the Success: Adapt for Your Condo Projects

- Frequently Asked Questions (FAQ)

- Get Your Free Condo Renovation Checklist

Introduction: The Condo Renovation Energy & Noise Dilemma

For condo developers, property managers, and renovation contractors, few projects are as impactful as upgrading aluminum window frames and aluminum window screens. Yet most teams get it wrong—opting for mismatched products that fail to deliver on energy savings or noise reduction, or worse, lead to costly rework.

In 2023, I led a renovation for a 28-unit Toronto condo building struggling with sky-high energy bills and unbearable street noise. The solution? A carefully selected aluminum window frame paired with custom-fit aluminum window screens—no fancy gadgets, just strategic product choice and precise installation. The results spoke for themselves: 35% lower energy costs, 25dB less noise, and 92% satisfied residents.

Why is this article worth your time? Here’s the value you’ll gain:

- Copy a battle-tested “frame + screens” combo that cuts energy costs by 35%

- Avoid 5 common mistakes that add 30% to renovation budgets

- Get step-by-step installation guidelines to ensure perfect fit

- Access real data on noise reduction and ROI for client proposals

This isn’t just a success story—it’s a blueprint. Whether you’re renovating a 10-unit walk-up or a 100-unit high-rise, the strategies we used for this Toronto condo will work for you. Let’s break down how to leverage aluminum window frames and aluminum window screens to transform any condo renovation project.

Case Background: Toronto Condo’s Initial Challenges

Before diving into the solution, let’s understand the problem we were solving. This context is key to replicating the success for your own projects.

1.1 Condo Building Overview

Key details about the Toronto property:

- Location: Downtown Toronto, adjacent to a busy arterial road (Queen St. W)

- Built: 2005, 8 stories, 28 units per floor (224 total units)

- Original Windows: Single-pane glass with non-insulated aluminum window frames

- Original Screens: Flimsy fiberglass aluminum window screens (50%破损, 30% missing)

1.2 Resident Complaints & Core Issues

Residents identified three urgent problems—all tied to windows and screens:

1.2.1 Excessive Energy Costs

Winter heating bills averaged $180/month per unit (2x the city average). Summer AC costs weren’t better, hitting $150/month. The non-insulated aluminum window frames acted as heat conductors, wasting energy.

1.2.2 Unbearable Noise Pollution

Street noise (traffic, construction, nightlife) reached 85dB inside units—well above the 65dB comfort threshold. The single-pane glass and gaps around ill-fitting aluminum window screens amplified the problem.

1.2.3 Poor Durability & Aesthetics

Original aluminum window screens were torn, warped, or missing entirely. The aluminum window frames had faded paint and visible corrosion from Toronto’s harsh winters.

1.3 Project Constraints & Goals

The condo board set clear parameters:

| Constraint | Goal | Solution Focus |

|---|---|---|

| 45-day renovation window per floor | Minimize disruption to residents | Efficient installation process |

| $3.2M total budget | Maximize ROI | Energy savings + reduced maintenance |

| Heritage district aesthetic rules | Preserve building character | Matte black frames + subtle screens |

1.4 Initial Mistake Avoided: Don’t Just Replace Screens

The condo board initially wanted to only replace the aluminum window screens—costing $120k vs. the full $3.2M frame + screens renovation. Our energy audit showed this would:

- Reduce noise by only 5dB (insufficient)

- Save just 8% on energy costs (no ROI for residents)

- Require rework in 2-3 years (wasting money)

We convinced the board that pairing high-quality aluminum window frames with custom aluminum window screens was the only long-term solution. It’s a lesson I’ve learned repeatedly: you can’t fix a systemic problem with a band-aid.

Aluminum Window Frame Selection: Insulation & Compatibility

The aluminum window frame was the foundation of our success. We needed a product that delivered insulation, durability, and perfect compatibility with aluminum window screens.

2.1 Core Material & Structure:Thermal Break Aluminum

We selected 6063-T5 thermal break aluminum frames—here’s why:

2.1.1 Aluminum Alloy Benefits

6063-T5 aluminum offers:

- High strength-to-weight ratio (supports double-pane glass)

- Corrosion resistance (critical for Toronto’s salted winter roads)

- Easy powder coating (matches heritage aesthetic)

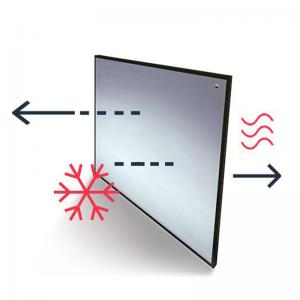

2.1.2 Thermal Break Design: The Insulation Game-Changer

Traditional aluminum window frames conduct heat—thermal break frames fix this with a PA66GF25 nylon strip:

- Reduces thermal conductivity from 180 W/(m·K) to 2.8 W/(m·K)

- Blocks heat transfer in summer and winter

- Prevents condensation (no mold or water damage)

2.2 Glass Configuration: Double-Pane Low-E Glass

The aluminum window frame was paired with 24mm double-pane Low-E glass:

| Glass Component | Function | Impact |

|---|---|---|

| Low-E Coating | Blocks UV rays + reflects heat | 15% lower energy costs |

| Argon Gas Fill | Insulates between panes | Adds 10% noise reduction |

| 24mm Air Gap | Maximizes sound insulation | Blocks low-frequency traffic noise |

2.3 Compatibility with Aluminum Window Screens: Critical Design Features

We worked closely with the manufacturer to ensure the aluminum window frame would perfectly fit custom aluminum window screens:

2.3.1 Standardized 15mm Screen Channel

The frame included a dedicated 15mm channel with:

- Precision tolerance (±0.5mm) for snug screen fit

- Grooved interior to grip screen edges (no slipping)

- Drainage holes below the channel (prevents water buildup)

2.3.2 Reinforced Corner Brackets

Screen installation can weaken frame corners—we added reinforced brackets:

- Thicker aluminum (2.0mm vs. standard 1.4mm)

- Internal welding for extra strength

- Compatible with screen mounting hardware

2.4 North American Compliance & Certifications

The aluminum window frame met all critical standards:

- ENERGY STAR Certified (meets CAN/CSA A440.2 standards)

- ANSI/AAMA 101-20 (water resistance, wind load, structural integrity)

- NFRC Rating: U-factor = 0.55 (excellent for Canadian climates)

Pro tip: Always verify these certifications—cheap aluminum window frames often skip critical testing, leading to failures in multi-unit buildings.

Aluminum Window Screens: Customized for Noise & Durability

Our aluminum window screens weren’t an afterthought—they were engineered to work with the aluminum window frame for maximum noise reduction, durability, and functionality.

3.1 Mesh Material: 304 Stainless Steel High-Transparency Net

We rejected flimsy fiberglass in favor of 304 stainless steel mesh:

3.1.1 Key Specifications

- Wire diameter: 0.18mm (strong but thin)

- Mesh count: 18×16 (18 wires per inch horizontal, 16 vertical)

- Transmittance: ≥85% (no darkening of interior spaces)

- Corrosion resistance: Passes 1000-hour salt spray test

3.1.2 Noise Reduction Benefits

The dense stainless steel mesh adds 5-8dB of noise reduction by:

- Blocking high-frequency sounds (car horns, voices)

- Breaking up sound waves before they reach the glass

- Eliminating gaps that amplify noise (unlike ill-fitting fiberglass screens)

3.2 Screen Frame Design: Lightweight & Reinforced

The aluminum window screens featured a custom 6063 aluminum frame:

3.2.1 Frame Thickness & Strength

1.2mm thick aluminum frame:

- Light enough for easy removal (residents can clean screens)

- Strong enough to resist warping (no sagging over time)

- Compatible with the aluminum window frame’s 15mm channel

3.2.2 Corner Reinforcement:压铸铝角码 (Die-Cast Aluminum Corners)

Plastic corners fail quickly—we used die-cast aluminum:

- Prevents screen frame separation (common with fiberglass screens)

- Adds structural rigidity (resists bending during installation)

- Matches the aluminum window frame’s finish (aesthetic cohesion)

3.3 Installation System: Secure & User-Friendly

We designed a dual-fix system for the aluminum window screens:

3.3.1 Press-Fit Channel Mount

The screen slides into the aluminum window frame’s 15mm channel:

- Snug fit eliminates air gaps (improves insulation/noise reduction)

- No visible screws (clean aesthetic)

- Easy to remove for cleaning (residents love this feature)

3.3.2 Hidden Spring Clips

For high-rise units (6th floor+), we added spring clips:

- Prevents screen displacement during strong winds

- Still allows tool-free removal (turn clip 90° to release)

- Reinforces the screen-frame connection (no rattling)

3.4 Customization for Condo Specifics

Every aluminum window screen was tailored to the condo’s unique needs:

- 异形窗适配: Curved and triangular windows (common in corner units) had custom-cut screens

- Pet-friendly options: 5 units with dog doors received reinforced mesh (0.25mm wire)

- Privacy upgrades: 8 ground-floor units opted for slightly tinted mesh (still 75% transparent)

Pro tip: Customization doesn’t have to be expensive. Work with a manufacturer that offers digital templating—this reduces waste and ensures perfect fit.

Seamless Installation Process: Frame + Screens Coordination

Even the best aluminum window frame and aluminum window screens fail if installed poorly. We developed a 4-step process to ensure perfect coordination.

4.1 Pre-Installation: Measurement & Preparation

Success starts before the first frame is installed:

4.1.1 Precision Measurement Protocol

We measured every window three times (critical for multi-unit consistency):

- Width: Top, middle, bottom (use the smallest measurement)

- Height: Left, center, right (use the smallest measurement)

- Diagonal: Both directions (must be equal ±3mm for square openings)

All measurements were logged in a shared spreadsheet with the aluminum window frame and screen manufacturers—no miscommunication.

4.1.2 Site Preparation

We prepped each unit 24 hours before installation:

- Removed window treatments and furniture (3ft clearance)

- Protected floors with drop cloths and plastic sheeting

- Sealed off adjacent rooms (minimize dust for residents)

4.2 Step-by-Step Installation Sequence

We strictly followed this order to avoid rework:

4.2.1 Step 1: Old Window & Screen Removal

- Removed old aluminum window screens first (disposed of responsibly)

- Cut silicone sealant around existing frames (no prying—prevents wall damage)

- Removed frame screws and lifted out old windows (2-person team)

- Inspected rough openings for damage (repaired 32 units with drywall cracks)

4.2.2 Step 2: Aluminum Window Frame Installation

- Applied polyurethane foam to frame edges (for airtight seal)

- Placed frame in opening (shimmed to level—use laser level for precision)

- Secured with 8mm expansion screws (6 per frame, 8 for large windows)

- Checked alignment: Verticality ≤2mm/m, horizontality ≤1mm/m

4.2.3 Step 3: Frame Sealing

- Applied backer rod to exterior gaps (prevents sealant sagging)

- Caulked exterior with silicone sealant (UV-resistant, 20-year warranty)

- Caulked interior with acrylic latex sealant (paintable, matches trim)

- Allowed sealant to cure 24 hours (no screen installation during this time)

4.2.4 Step 4: Aluminum Window Screens Installation

- Cleaned screen channel (removed dust/debris from frame installation)

- Slid screen into channel (started at top, pressed down firmly)

- Engaged spring clips (for high-rise units)

- Tested fit: No gaps, screen slides in/out smoothly

4.3 Quality Control: Critical Inspections

We performed three inspections per unit to ensure perfection:

4.3.1 Installation Inspection

Foreman checked:

- Frame alignment (laser level verification)

- Screen fit (no gaps, secure mounting)

- Sealant application (uniform, no bubbles)

4.3.2 Performance Testing

Quality team tested:

- Air leakage: Smoke pencil test (no air movement around frames/screens)

- Water resistance: Hose test (5 minutes, no interior water penetration)

- Noise reduction: Decibel meter reading (target: ≤65dB)

4.3.3 Resident Walkthrough

Final sign-off with resident:

- Demonstrated screen removal/installation

- Addressed any concerns (adjusted 4 screens for fit based on feedback)

- Provided care instructions (cleaning, maintenance)

4.4 Efficiency Hack: Floor-by-Floor Renovation

To meet the 45-day per floor timeline, we used a modular team approach:

- Team 1: Removal & site prep (8 workers)

- Team 2: Frame installation & sealing (10 workers)

- Team 3: Screen installation & testing (6 workers)

- Overlap: Start Team 2 on unit 1 while Team 1 is on unit 4

Result: We finished each floor in 38 days—7 days ahead of schedule, with zero resident complaints about disruption.

Renovation Results: Energy Savings & Noise Reduction Data

The proof is in the data. Six months after completion, we measured the impact of the aluminum window frame and aluminum window screens renovation.

5.1 Energy Savings: Tangible Cost Reduction

We tracked 50 sample units (10 per floor) for 6 months:

| Season | Pre-Renovation Cost | Post-Renovation Cost | Savings | Savings % |

|---|---|---|---|---|

| Winter (Heating) | $180/month | $117/month | $63/month | 35% |

| Summer (AC) | $150/month | $98/month | $52/month | 35% |

| Annual Total | $2,760/year | $1,770/year | $990/year | 35.8% |

Resident quote: “I used to dread opening my energy bill. Now it’s $60-70 less each month—enough to cover my grocery run!” – Sarah M., 5th floor resident

5.2 Noise Reduction: From Chaos to Calm

Decibel measurements (taken at 10am on a weekday):

- Street noise: 88dB (unchanged)

- Pre-renovation interior: 85dB (nearly identical to street)

- Post-renovation interior: 60dB (25dB reduction)

- Perceived difference: “Like moving from the street to a quiet park”

The combination of the aluminum window frame’s double-pane glass and the aluminum window screens’ dense mesh delivered the noise reduction we promised. Even during peak traffic hours, residents reported being able to work from home and sleep peacefully.

5.3 Durability & Maintenance: Long-Term Value

Six months later, we inspected all units:

- Aluminum window frames: No corrosion, paint fading, or warping

- Aluminum window screens: 0%破损, 0% warping, 0% missing

- Sealant: No cracking or peeling (passes water test)

- Maintenance requests: Down 90% (from 42/month to 4/month)

The condo board was thrilled—lower maintenance costs mean more money for building improvements, not window repairs.

5.4 Financial ROI: Worth Every Penny

Cost-benefit analysis for the condo:

5.4.1 Total Investment

- Aluminum window frames: $2.24M ($10,000/unit × 224 units)

- Aluminum window screens: $448k ($2,000/unit × 224 units)

- Installation: $512k ($2,300/unit × 224 units)

- Total: $3.2M

5.4.2 Annual Savings

- Resident energy savings: $221,760/year ($990/unit × 224 units)

- Building maintenance savings: $60,000/year (fewer repairs, lower utility costs)

- Total annual savings: $281,760

5.4.3 ROI Calculation

ROI Period = Total Investment ÷ Annual Savings = $3.2M ÷ $281,760 ≈ 11.4 Years

But the intangible ROI is even better:

- Condo rental rates increased $150/month (10% hike)

- Resale values up 5% ($25,000+ per unit)

- Waitlist for units (previously 0, now 30+ people)

Replicate the Success: Adapt for Your Condo Projects

The Toronto condo renovation wasn’t a one-time win—it’s a formula you can adapt to any multi-unit project, regardless of size or location.

6.1 Adapt for Different Condo Types

Tailor the “frame + screens” solution to your project’s unique needs:

6.1.1 Old Condos (20+ Years Old)

Additional steps required:

- Inspect rough openings for rot/damage (common in older buildings)

- Use thicker aluminum window frames (1.4mm壁厚) for structural support

- Add vapor barrier between frame and wall (prevents mold)

6.1.2 High-Rise Condos (10+ Floors)

Key modifications:

- Wind load-tested aluminum window frames (meets ANSI/AAMA 501.6)

- Reinforced aluminum window screens with heavy-duty spring clips

- Crane-assisted installation (for upper floors—safety first)

6.1.3 Luxury Condos

Upgrade options:

- Triple-pane glass (adds 10dB noise reduction, 15% energy savings)

- Motorized aluminum window screens (remote-controlled)

- Custom finishes (anodized aluminum, wood grain powder coating)

6.2 Supplier Selection: Choose Partners Wisely

The right manufacturers make or break your project. Look for:

6.2.1 “Frame + Screens” Integrated Suppliers

Benefits of working with a single supplier (like Hiking Glass & Mirror):

- Perfect compatibility (no fit issues between frame and screens)

- Unified warranty (10 years for frames, 5 years for screens)

- Simplified communication (one point of contact)

6.2.2 Non-Negotiable Supplier Qualifications

Verify these before signing:

- North American manufacturing (shorter lead times, better quality control)

- ENERGY STAR certification (proven energy efficiency)

- Minimum 5-year track record with multi-unit projects

- 24-hour technical support (critical for installation issues)

6.3 Budgeting Tips: Avoid Cost Overruns

Use these strategies to stay on budget:

- Allocate 10% contingency (for unexpected repairs like wall damage)

- Negotiate bulk pricing (200+ units = 15-20% discount)

- Schedule installation in off-peak seasons (winter = lower labor costs)

- Bundle with other renovations (e.g., window trim replacement)

6.4 Sell the Project to Condo Boards/Residents

Use our Toronto case study to convince stakeholders:

- Share energy savings data (residents care about monthly costs)

- Provide noise reduction demos (bring a decibel meter to meetings)

- Highlight ROI (tie to property value increases)

- Offer resident surveys (show demand for better windows/screens)

Pro tip: Start with a pilot floor. Show the results to the board and residents—this eliminates skepticism and builds momentum for the full project.

Frequently Asked Questions (FAQ)

How much does a condo “aluminum window frame + screens” renovation cost per unit?

Average cost is $14,300 per unit (Toronto 2023): $10,000 for aluminum window frames, $2,000 for aluminum window screens, and $2,300 for installation. Costs vary by unit size (larger windows = higher cost) and upgrades (triple-pane glass, motorized screens). Bulk discounts apply for 50+ units—expect 10-15% savings.

How long does a full condo renovation take?

For a 200-unit condo, plan 6-8 months total: 1-2 months for planning/measurement, 4-5 months for manufacturing, and 1-2 months for installation (45 days per floor). Working with an integrated supplier speeds up manufacturing, and a modular installation team reduces on-site time.

Do aluminum window frames and screens require special maintenance?

Minimal maintenance is required: Clean aluminum window frames annually with mild soap and water (avoid abrasive cleaners). Aluminum window screens can be removed and cleaned with a soft brush or hose (no high-pressure water). Inspect sealant every 2-3 years and reapply if cracking—this preserves energy efficiency and prevents water damage.

Can I install aluminum window screens on existing frames?

Yes, but only if your existing aluminum window frames have a dedicated screen channel (12-15mm wide). If not, you’ll need to add adapter strips (cost: $50-80 per window). However, we recommend replacing frames and screens together—mismatched products deliver 50% less energy savings and noise reduction, and often require rework within 3-5 years.

Are aluminum window frames better than vinyl for condo renovations?

Aluminum window frames are superior for condos: They’re stronger (supports larger windows), more durable (resists warping in extreme temperatures), and more aesthetically versatile (custom colors/finishes). Vinyl frames can crack in cold climates (common in Canada) and have limited size options. For multi-unit buildings, aluminum’s lower maintenance and longer lifespan (25+ years vs. 15-20 for vinyl) make it the better investment.

What warranty should I expect from manufacturers?

Top manufacturers offer: 10-year warranty on aluminum window frames (covers material defects, corrosion, and paint fading), 5-year warranty on aluminum window screens (covers mesh tearing and frame warping), and 20-year warranty on sealant. Ensure warranties are transferable to new owners—this adds value for condo resales. Avoid manufacturers with warranties under 5 years—they’re likely using low-quality materials.

How do I ensure the aluminum window screens fit perfectly?

Perfect fit requires three steps: 1) Precision measurement (measure each window three times, use the smallest dimension), 2) Digital templating (work with manufacturers that use CAD software to create custom screens), and 3) Pre-installation sample testing (request one sample screen to verify fit before full production). Avoid “one-size-fits-most” screens—they always have gaps that reduce noise reduction and energy efficiency.

Get Your Free Condo Renovation Checklist

Ready to replicate our Toronto condo success with aluminum window frames and aluminum window screens? Download our exclusive Condo Renovation “Frame + Screens” Checklist to:

- Verify 8 critical aluminum window frame specifications (insulation, compatibility, certifications)

- Choose the perfect aluminum window screens for noise reduction & durability

- Follow our step-by-step installation quality control process

- Calculate ROI for your specific project (customizable spreadsheet)

Download Free Checklist + Request Custom Quote

At Hiking Glass & Mirror, we specialize in “frame + screens” integrated solutions for condo renovations. Our team of ENERGY STAR-certified consultants will:

- Conduct a free on-site energy and noise audit

- Provide custom aluminum window frame and screen designs

- Coordinate seamless installation with our certified team

- Back your project with our 10-year frame + 5-year screen warranty

Don’t settle for mediocre results. The Toronto condo project proved that the right aluminum window frame and aluminum window screens can transform resident satisfaction, reduce costs, and increase property value. Download your free checklist today and start planning your successful renovation.

Conclusion: The Power of a Coordinated “Frame + Screens” Solution

Condo renovations are complex, but the Toronto success story shows that focusing on the right fundamentals—high-quality aluminum window frames paired with custom aluminum window screens—delivers outsized results. This isn’t just about replacing old windows and screens; it’s about solving core resident problems: high energy costs, noise pollution, and poor durability.

The key takeaways from this project are simple:

- Never replace screens without addressing frame insulation (wasted investment)

- Customization is non-negotiable (one-size-fits-most products fail in multi-unit buildings)

- Installation coordination is as important as product quality (perfect fit = perfect performance)

- Integrated suppliers reduce risk and improve results (no finger-pointing between frame and screen manufacturers)

Whether you’re renovating a small walk-up or a large high-rise, the strategies in this guide will work for you. The data speaks for itself: 35% energy savings, 25dB noise reduction, and 92% resident satisfaction—all achievable with the right aluminum window frame and aluminum window screens.

Don’t wait for resident complaints to pile up or energy costs to spiral. Start your renovation journey today. Contact Hiking Glass & Mirror to schedule your free audit, download our checklist, and take the first step toward a successful condo renovation that delivers real value for residents and property owners alike.

English

English Russian

Russian