Acid Etched Glass Design: 7 Applications Beyond Privacy [Factory Guide]

Table of Contents

- Acid Etched Glass Reimagined: From Functional Material to Artistic Medium

- Application 1: The Luminous Divide – Dynamic Interior Partitions

- Application 2: Branded Environments – Integrating Identity into Architecture

- Application 3: The Art of Light – Feature Walls & Installations

- Application 4: Elevated Furniture & Decorative Elements

- Application 5: Sophisticated Façade Elements & Solar Control

- Application 6: The Luxury Bathroom – Redefined

- Application 7: The Hybrid Approach – Combining Technologies

- Conclusion: Your Next Step

- Frequently Asked Questions (FAQ)

Let’s be brutally honest for a second. When you hear “acid etched glass,” what’s the first image that pops into your head? If it’s a boring, plain frosted shower door or a basic office partition, you’re not alone. That’s the commodity view. But what if I told you that perspective is costing you and your clients extraordinary design opportunities?

For over a decade, I’ve watched architects and designers specify this material with a fraction of its potential in mind. They come to us, a professional acid etched glass factory, asking for “standard frosted glass,” only to be stunned when we show them what’s truly possible. This article is your wake-up call and your definitive guide. We’re moving far beyond privacy. Here, you’ll discover seven transformative applications that turn acid etched glass from a supporting actor into the star of your project. You’ll learn not just the “what,” but the crucial “how” and “why” from a manufacturing insider’s view. This isn’t just inspiration; it’s a practical blueprint for specification that will save you time, prevent costly errors, and unlock stunning results.

Acid Etched Glass Reimagined: From Functional Material to Artistic Medium

Before we dive into the applications, let’s reset our understanding. Acid etching isn’t just a coating; it’s a permanent modification of the glass surface. We use hydrofluoric acid to precisely micro-etch the glass, creating a smooth, satin-matte finish that scatters light beautifully.

What Makes It So Versatile? The Science Behind the Beauty

The magic lies in that uniform, crystalline surface. Unlike films or sandblasting (which can be uneven), acid etching provides exceptional consistency. This consistency is what gives designers a reliable canvas. It offers translucency, not opacity, allowing light to permeate while softening views and eliminating harsh glare.

Beyond Basic Frosting: The Power of Custom Patterns

This is where the real design revolution happens. As a modern acid etched glass supplier, our core work isn’t producing blank frosted sheets. It’s translating your vision. Using resistant stencils derived from digital artwork, we can etch any pattern: intricate geometric designs, flowing organic shapes, corporate logos, or photorealistic imagery. The glass becomes a direct print of your creativity.

Application 1: The Luminous Divide – Dynamic Interior Partitions

Open-plan spaces are popular, but they often create a dilemma: how to define areas without building dark, claustrophobic walls. Standard clear glass feels too exposed, while solid walls kill the light and open feel.

The Acid Etched Solution: Light-Filled Privacy & Zone Definition

Acid etched glass partitions are the elegant answer. They provide a soft visual barrier that maintains spatial continuity and light flow. We’ve installed them in corporate offices to create focused team hubs, in luxury restaurants to define private dining nooks, and in homes to separate living areas without sacrificing the sense of space.

Design Tip: Strategic Patterning for Functional Needs

The key is intentional pattern selection. You control the level of privacy and visual connection through design density.

| Pattern Density | Light Transmission | Visual Privacy | Ideal Use Case |

|---|---|---|---|

| High Density (80-95% coverage) | Low (10-20%) | Very High | Executive offices, confidential meeting rooms, bathroom enclosures. |

| Medium Density (40-60% coverage) | Medium (30-50%) | Moderate | Team partitions, reception areas, semi-private dining zones. Shapes remain discernible. |

| Low Density / Gradients | High (60%+) | Low to Symbolic | Space definition in lobbies, decorative screens, artistic elements where light is primary. |

Pro Insight from the Factory: Always discuss panel sizes and framing early with your acid etched glass factory. For a seamless, floor-to-ceiling look, we can produce oversized panels (up to 3300x6000mm for some patterns), minimizing visible joints and frames.

Application 2: Branded Environments – Integrating Corporate Identity into Architecture

Companies spend millions on logos and brand guides, yet their physical headquarters often fail to embody that identity in a lasting, architectural way. Vinyl decals peel. Painted walls get repainted.

Etching Logos & Motifs: Permanent, Sophisticated Branding

Etching your logo or brand pattern directly into glass is a powerful statement of permanence and quality. It’s integrated into the building fabric. We’ve created stunning feature walls for tech company lobbies, etched subtle brand motifs across entire office floor glazing, and produced branded meeting room dividers for law firms.

Case Study: "Nexus Tech" Headquarters Lobby Transformation

Challenge: Nexus Tech wanted their new lobby to scream innovation, not just say it. A plain glass reception desk felt cold. They needed a "wow" factor that embodied their circuit-board-inspired logo.

Our Solution as Their Acid Etched Glass Supplier: We took their high-resolution vector file and etched it across a 12-meter-long, 3-meter-high back-painted (deep blue) acid etched glass feature wall behind reception. The etching was precise to 0.5mm detail.

Result: The wall became an immediate talking point. During the day, natural light revealed the intricate pattern subtly. At night, integrated LED backlighting made the entire "circuit board" glow, creating a breathtaking beacon. It wasn’t just decor; it was the brand experience.

Application 3: The Art of Light – Feature Walls and Sculptural Installations

Blank walls are missed opportunities. Acid etched glass, when combined with light, becomes a dynamic, interactive art piece.

Transforming Walls into Interactive Light Canvases

Imagine a corridor wall that changes character from day to night. By etching a custom pattern and strategically lighting it, you create an ever-changing element of depth and interest.

Mastering Backlighting Techniques

The lighting method drastically alters the effect. Here’s what we guide our clients on:

- Uniform Backlighting (LED Panels): Creates a clean, glowing "lightbox" effect. Perfect for ensuring even illumination of logos or graphic patterns.

- Edge-Lighting (LED Strips): Produces a soft, gradient glow that is brightest at the edges. Ideal for creating a halo effect or emphasizing the perimeter of a panel, adding depth and modernity.

- Front Grazing Light: Positioning lights to skim the surface highlights the tactile, matte texture of the etch, creating dramatic shadows and emphasizing the pattern’s physicality.

Collaboration in Action: From Sketch to Glowing Reality

The success of a lit feature wall hinges on early collaboration. As your acid etched glass factory, we need to understand the lighting plan during the design phase. The thickness of the glass, the depth of the etch, and the color of any back-painting all interact with light differently. Providing a small, lit sample before full production is non-negotiable for high-stakes projects.

Application 4: Elevated Furniture & Decorative Elements

The demand for bespoke, high-end furnishings is soaring. Acid etched glass adds a layer of custom luxury that mass-produced items cannot match.

Tabletops, Cabinets, and Decorative Panels

We’ve produced:

- Conference Tabletops: Etched with a company’s core values or a subtle map motif.

- Luxury Retail Cabinet Fronts: A frosted background makes products pop, while etched brand details add sophistication.

- Fireplace Surrounds & Room Dividers: Etched with nature-inspired patterns to bring organic calm into a living space.

Material Synergy: The Perfect Partnerships

Acid etched glass doesn’t exist in a vacuum. Its true beauty shines in combination.

- With Wood: The warm, organic grain of walnut or oak against the cool, smooth frost creates a timeless, balanced aesthetic.

- With Metal: Brushed brass or matte black steel frames complement the satin finish of the glass perfectly, defining edges and adding structural elegance.

- With Stone: A frosted glass insert in a marble or sintered stone countertop breaks up a large surface, adding visual interest and functionality.

Application 5: Sophisticated Façade Elements and Solar Control

Building exteriors need to be more than just skin-deep. Acid etched glass can play a crucial functional and aesthetic role here.

Adding Texture and Depth to Building Skins

Used as spandrel glass (the opaque panels between floors that hide structural elements), etched patterns can add rhythm and texture to a façade. Instead of a flat, monochromatic wall, you get a subtle, layered effect that changes with the sun’s angle.

The Functional Benefit: Glare and Heat Reduction

A densely etched pattern on an outer layer of an insulated glazing unit (IGU) can significantly reduce solar heat gain and glare inside the building. This isn't its primary function like a frit, but it’s a valuable secondary benefit that makes the design choice more compelling to engineers and sustainability-focused clients.

Application 6: The Luxury Bathroom – Redefined

Yes, we started by moving beyond the bathroom, but let’s circle back to revolutionize it. The standard clear or fully frosted shower screen is a missed opportunity for serenity.

Creating a Spa-like Ambiance with Patterned Wet Areas

Imagine a shower enclosure etched with a gentle, vertical line pattern mimicking rain, or a bamboo forest scene. It transforms a daily routine into a sensory experience. The diffused light, the soft visual texture—it’s about crafting an atmosphere, not just enclosing a space.

Critical Factory Note: For shower applications, the acid etched glass must be properly tempered for safety. The etching process is done before tempering. A reputable acid etched glass factory will always ensure this sequence and provide the necessary safety certifications.

Application 7: The Hybrid Approach – Combining Etching with Other Technologies

This is where expert acid etched glass suppliers truly differentiate themselves. Layering processes unlocks unparalleled creativity.

Acid Etching + Back-Painting: Vivid Color and Texture

Etch first, then apply a durable ceramic paint to the back. The paint adheres brilliantly to the etched surface. You get a vibrant, opaque color from one side, with the beautiful satin texture visible from the other (etched) side. Perfect for bold brand colors or specific Pantone matches in signage and interior features.

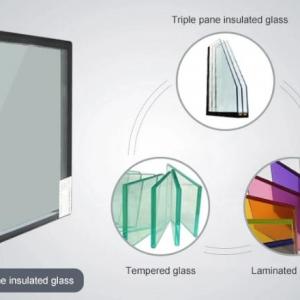

Acid Etching + Lamination: Ultimate Safety & Design Freedom

For overhead applications, balustrades, or areas requiring impact resistance, we laminate the etched glass with another sheet of glass (clear or tinted) using a PVB interlayer. This creates a safety glass that retains your custom etched design. You can even sandwich decorative elements (fabrics, metals) between the layers for stunning effects.

Conclusion: Your Next Step Towards Transformative Design

Acid etched glass is not a mundane material to be ordered from a catalog. It’s a collaborative design tool with near-limitless potential. The seven applications we’ve explored—from luminous partitions and branded walls to illuminated art and hybrid creations—are just the starting point.

The common thread in every successful project is a close partnership between the creative mind and a technically proficient acid etched glass factory. It’s about asking “what if?” and having a partner who can answer with a feasible, beautiful solution.

Don’t let your next project settle for ordinary. Bring your most ambitious glass idea to a partner who understands both art and engineering.

Ready to See What’s Possible for Your Specific Design?

Get Your Free Design Feasibility Review

Send us your concept sketch, vector file, or just a description of your vision. Within 12 hours, our design and engineering team will provide initial feedback on manufacturability, technical considerations, and a ballpark cost guide. No obligation, just professional insight.

Frequently Asked Questions (FAQ)

1. How durable is an acid etched finish? Can it wear off or be scratched?

The etch is permanent. Since the surface layer of the glass is chemically modified, the frosted effect cannot peel, flake, or wear off with cleaning. Its hardness is identical to the original glass, making it highly scratch-resistant under normal use.

2. What file format do I need to provide for a custom pattern?

Vector files (AI, EPS, PDF) are ideal for crisp, scalable results like logos and geometric patterns. For photorealistic or complex grayscale images, a high-resolution (300 DPI) TIFF or PSD file works. Our team can often help optimize artwork.

3. What's the difference between acid etched glass and sandblasted glass?

Acid etching produces a smoother, more consistent, and finer satin finish. Sandblasting can be more abrasive, creating a rougher, more "gritty" texture that is harder to clean and can appear less uniform, especially on large panels. Acid etching allows for much sharper detail in custom patterns.

4. Can acid etched glass be used outdoors?

Absolutely. The etched surface is highly weather-resistant. For long-term exterior performance, it is often used as part of an insulated glass unit (IGU) or laminated for structural and safety reasons. An experienced acid etched glass supplier will advise on the best construction for your climate and application.

5. How do I clean and maintain acid etched glass?

Use a standard glass cleaner and a soft, non-abrasive cloth or microfiber towel. The textured surface may hold water spots slightly more than clear glass, so drying with a clean cloth after cleaning is recommended for a streak-free shine.

6. What are the lead times for custom etched glass?

For standard sizes and patterns, production can be 10-15 working days. Complex custom designs, oversized panels, or hybrid processes (like etching + laminating) may take 3-5 weeks. We always provide a clear timeline upon project review.

Further Reading & Resources

To deepen your knowledge on architectural glass, explore these related articles:

English

English Russian

Russian