Green Building 2026: The Eco-Tech Behind Aluminum Clad Wood & Storm Windows

Green Building Revolution: How Aluminum Clad Wood Windows Are Reducing Carbon Footprints Worldwide

Table of Contents

- Introduction: The High Cost of Wasted Energy

- Part 1: The Unsustainable Cost of Ordinary Windows

- Part 2: The Science of Superior Performance

- Part 3: Quantifying the Green: Savings & ROI

- Part 4: Navigating Your Sustainable Project

- Conclusion & Your Next Step

- Frequently Asked Questions (FAQ)

- References & Further Reading

Introduction: The High Cost of Wasted Energy

Every winter, a familiar dread creeps in alongside the cold: skyrocketing heating bills. Every summer, air conditioners groan under the strain, consuming electricity at an alarming rate. For decades, we've accepted this as the unavoidable cost of comfort. But what if the biggest culprit wasn't your furnace or AC unit, but the very windows meant to connect you with the outdoors? The truth is, inefficient windows act as a massive drain on your wallet and our planet's resources.

This article is your definitive guide to breaking free from that cycle. We're going deep on one of the most powerful upgrades in modern construction: aluminum clad wood windows. Why is this article worth your time? Because it moves beyond sales pitches. We'll provide you with the engineering principles, hard data, and real-world case studies that prove how these windows slash energy use, cut carbon emissions, and deliver a stunning return on investment. You'll learn not just what they are, but how they work, why they outperform every alternative, and exactly how much you could save.

The green building revolution is here, and high-performance fenestration is at its forefront. Whether you're a homeowner planning a renovation, a builder aiming for LEED certification, or an architect designing for the future, understanding aluminum clad wood windows is no longer optional—it's essential. Let's explore how this hybrid marvel is redefining efficiency, one opening at a time.

Part 1: The Unsustainable Cost of Ordinary Windows

Before we celebrate the solution, we must diagnose the problem with clarity. Standard, single-pane, or poorly sealed windows are not just weak spots; they are active liabilities.

Why Your Current Windows Are Costing You More Than Money

Think of your home's thermal envelope as a sealed balloon. A tiny leak seems insignificant until the balloon goes flat. Windows, especially old or low-quality ones, are often the primary leaks.

The Energy Leak: Understanding Thermal Bridging and Air Infiltration

Thermal bridging occurs when conductive materials (like basic aluminum frames) create a direct path for heat to flow between the inside and outside. It's like a metal spoon left in a hot soup—the handle gets hot. In winter, your precious indoor warmth escapes along the frame. In summer, exterior heat streams in.

Air infiltration is the sneaky draft you feel on a windy day. It’s uncontrolled airflow through gaps in the window assembly. This doesn't just make you cold; it forces your HVAC system to work constantly to replace lost conditioned air. According to the U.S. Department of Energy, air leakage can account for 25-30% of residential heating and cooling costs.

The Silent Environmental Impact of Inefficient Glazing

The financial pain is immediate, but the environmental cost is profound. The building sector is responsible for nearly 40% of global energy-related carbon emissions. Windows contribute significantly to this figure. Inefficient glazing leads to:

- Over-sized HVAC systems: Builders must install larger, more energy-intensive heating and cooling units to compensate for the loss.

- Increased fossil fuel consumption: Most heating still relies on natural gas or oil, directly tying window performance to greenhouse gas emissions.

- Shorter equipment lifespan: Constant overwork leads to more frequent repairs and replacements, creating more manufacturing and waste.

Upgrading your windows isn't merely a home improvement; it's a direct reduction of your carbon footprint.

Part 2: The Science of Superior Performance: Deconstructing Aluminum Clad Wood Windows

Now, let's dismantle the myth that beautiful windows can't be ultra-efficient. Aluminum clad wood windows are a masterclass in material science and smart engineering, designed to tackle the problems we just outlined head-on.

Engineering for Efficiency: What Makes Them a Game-Changer

The genius lies in the hybrid design. It leverages the inherent strengths of two materials while mitigating their weaknesses.

Hybrid Design, Maximum Benefit: The Best of Both Worlds

- The Wood Interior: Wood is a natural thermal insulator, approximately 1,800 times more resistant to heat flow than aluminum. The interior wood frame acts as a warm, non-conductive surface, minimizing condensation and cold spots. It provides the classic aesthetic warmth and design flexibility architects and homeowners love.

- The Aluminum Exterior: The extruded aluminum cladding is a rugged, low-maintenance shield. It protects the wood from sun, rain, snow, and physical damage. This cladding is available in a vast array of colors and finishes, allowing for bold architectural statements without sacrificing durability.

This combination delivers durability outside, warmth inside, and exceptional performance in the middle.

The Heart of Efficiency: Advanced Thermal Break Technology Explained

This is the single most critical feature. A "thermal break" is a non-metallic, highly insulating barrier inserted between the interior and exterior aluminum surfaces of the cladding.

| Thermal Break Material | Description | Key Advantage |

|---|---|---|

| Polyamide (Nylon) Strip | A rigid, durable plastic strip mechanically locked into the aluminum profile. | Excellent structural integrity and long-term thermal stability. |

| Polyurethane Foam Infill | Liquid foam injected into the cavity, which then hardens. | Creates a complete seal with no air pockets; good for complex profiles. |

This break stops thermal bridging in its tracks. It dramatically increases the frame's overall R-value (insulating power) and lowers its U-factor (heat loss rate). A high-quality thermal break can improve the window's performance by over 50% compared to a non-thermal break aluminum window.

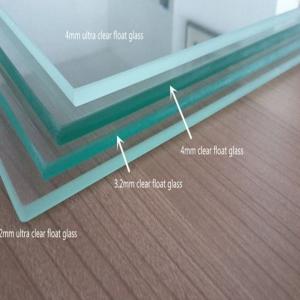

Sealing the Deal: Multi-Chambered Frames and Glazing Options

The innovation continues within the frame and sash profiles. Modern aluminum clad wood windows feature multi-chambered designs.

- These chambers (hollow spaces within the frame) trap still air, creating additional layers of insulation.

- They also house multiple, continuous compression seals—often made of EPDM rubber—that form an airtight gasket when the window is closed.

Pair this with advanced glazing, and the performance soars:

- Double-Pane Low-E with Argon: The standard for high performance. Low-E coating reflects infrared heat, and argon gas between the panes reduces conductive heat transfer.

- Triple-Pane Glazing: For extreme climates or Passive House projects, a third pane and an additional gas fill (like krypton) create a formidable thermal barrier, achieving U-factors as low as 0.15.

This holistic approach to sealing—thermal break + multi-chamber frame + compression seals + advanced glass—is what sets these windows apart.

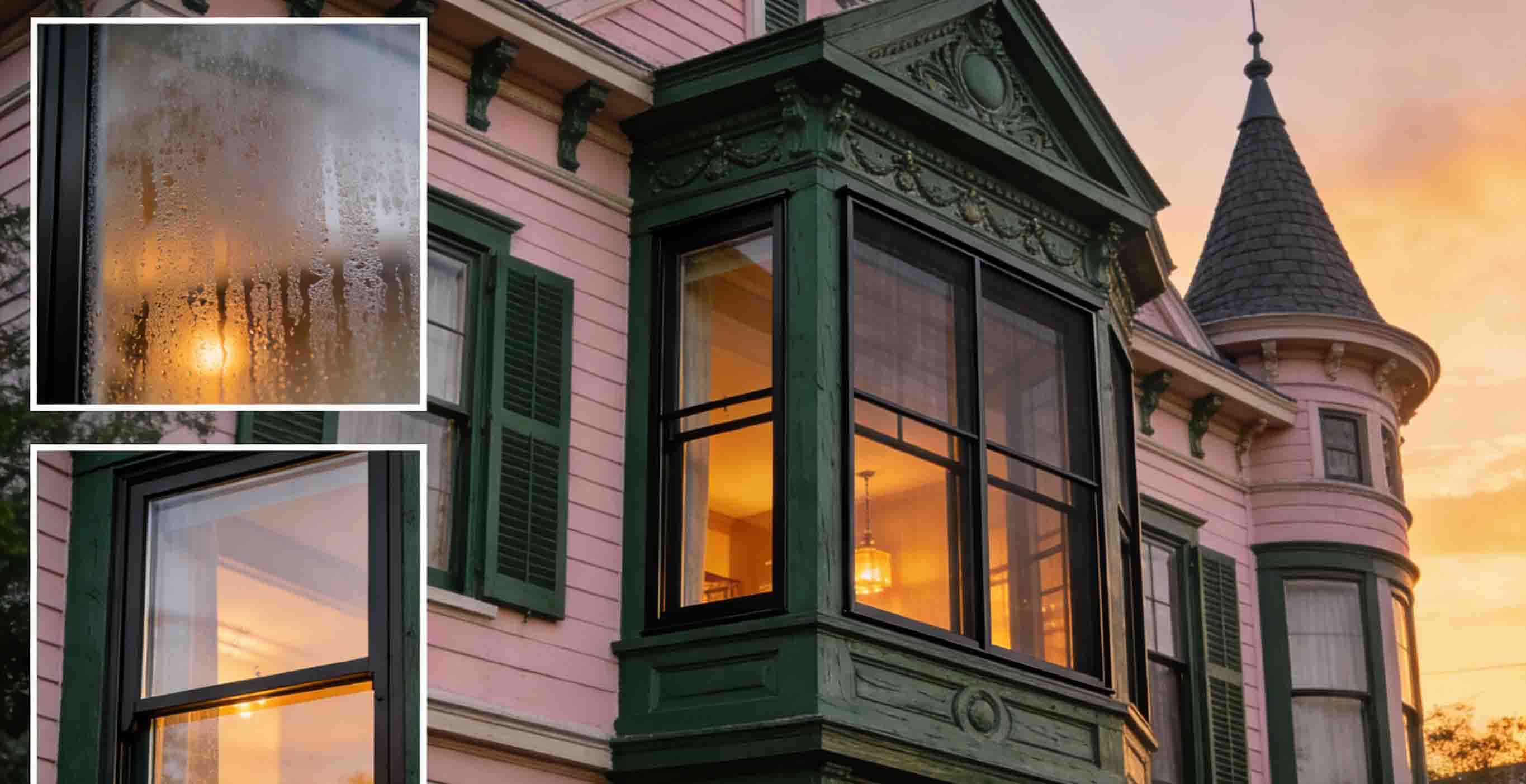

Where Do aluminum storm windows and Sliding Styles Fit In?

Understanding the full ecosystem is key. While aluminum clad wood windows are often the primary upgrade, complementary products enhance specific scenarios.

- aluminum storm windows: These are secondary windows installed on the exterior of existing primary windows. For historic homes where replacing original wood windows is restricted, adding a well-sealed aluminum storm window creates a dead air space that significantly boosts insulation and reduces drafts. It’s a respectful, high-impact retrofit.

- Aluminum Sliding Windows: Modern aluminum sliding windows have evolved. High-end versions now incorporate thermal breaks and multi-point locking systems that press the sash firmly against compression seals. They offer excellent panoramic views and ventilation control while meeting stringent energy codes, making them ideal for contemporary designs.

Part 3: Quantifying the Green: Energy Savings, Certifications & ROI

Let's translate engineering into tangible benefits. How do these windows perform in the real world, and what does it mean for your wallet and project goals?

Energy Star, LEED, and Passive House: Meeting Stringent Green Standards

Performance is measured against benchmarks. High-performance aluminum clad wood windows are gateways to prestigious certifications.

- ENERGY STAR®: The most recognized symbol for energy efficiency. To qualify, windows must meet strict U-factor and Solar Heat Gain Coefficient (SHGC) ratings set by the EPA for your specific climate zone. Our windows consistently exceed these requirements.

- LEED (Leadership in Energy and Environmental Design): Using certified windows can earn crucial points in the "Energy & Atmosphere" and "Materials & Resources" categories, helping a building achieve Silver, Gold, or Platinum status.

- Passive House (Passivhaus): This is the pinnacle. Passive House standards demand incredibly low U-factors (typically ≤ 0.14 for windows). Only windows with superior thermal breaks, triple glazing, and perfect seals can qualify. We engineer specific lines to meet this rigorous standard.

Case Study: "The Maple Passive Retrofit"

Project: A 1980s suburban home in Climate Zone 5 (Chicago area).

Problem: High heating bills ($2,800/year), cold drafts, and single-pane windows.

Solution: Replaced 18 existing windows with Hiking Glass triple-pane aluminum clad wood windows (U-factor: 0.20). Added aluminum storm windows on three large, historic-style fixed panes in the living room.

Result (12-month monitoring):

- Heating bill reduced by 42% (saving $1,176/year).

- Overall home energy use down by 31%.

- Eliminated drafts and improved indoor comfort dramatically.

- Estimated CO2 emission reduction: 3.2 tons annually.

"The comfort change was immediate. The house is silent now, no more wind noise. The payback period on our investment will be under 10 years, and then it's pure savings." – Homeowner Testimonial.

Calculating Your Potential Savings: A Simple Framework

You can estimate your own savings. While a professional energy audit is best, this gives you a ballpark.

- Find Your Baseline: Look at your annual heating and cooling costs (from utility bills).

- Estimate Window Contribution: The DOE estimates that windows account for 25-30% of that total. Use 30% for older homes.

- Apply an Efficiency Factor: Upgrading to high-performance windows can reduce that window-related loss by 50-70%. Use a conservative 50%.

- Do the Math: (Total Energy Cost) x 0.30 x 0.50 = Estimated Annual Savings.

Example: $3,000 annual energy bill x 0.30 x 0.50 = $450 saved per year. If the window project costs $18,000, the simple payback is 40 years. However, this does NOT account for: rising energy prices, increased home value, improved comfort/health, tax credits/incentives, or reduced maintenance costs. The true financial picture is much more favorable.

Part 4: Navigating Your Sustainable Window Project

Armed with knowledge, you're ready to specify and select. Here’s how to ensure you get windows that deliver on their promises.

Key Performance Indicators (KPIs) to Demand from Your Supplier

Don't just ask for "good windows." Ask for the data from independent testing (like NFRC ratings in North America).

- U-Factor: Measures heat loss. Lower is better. Look for ≤ 0.30 for double-pane, ≤ 0.20 for triple-pane in most climates.

- Solar Heat Gain Coefficient (SHGC): Measures solar heat admitted. Lower is better for hot climates, a moderate value may be desired for passive solar gain in cold climates.

- Visible Transmittance (VT): Measures light allowed through. Higher is better for daylighting.

- Air Leakage (AL): Measured in cubic feet per minute per square foot. Lower is better. Look for ≤ 0.3 cfm/ft².

- Design Pressure (DP): Measures structural strength against wind and water. Higher numbers indicate better performance in severe weather.

Questions to Ask: Ensuring True Sustainability

True green building looks at the entire lifecycle.

- "What is the source of the interior wood? Is it FSC-certified or from sustainably managed forests?"

- "What is the recycled content of the exterior aluminum cladding?" (Many quality suppliers use high recycled content).

- "How does your manufacturing process minimize waste and energy use?"

- "Can you provide a life cycle assessment (LCA) for the product?"

- "What is the expected service life, and what are the end-of-life recycling options?"

The Hiking Glass Difference: Engineering with the Future in Mind

At Hiking Glass, our approach is built on precision and responsibility. We don't just follow standards; we aim to set them.

- Precision Customization: We build to your exact specifications, minimizing on-site waste and ensuring a perfect fit for maximum performance.

- Material Integrity: We source premium, thermally modified woods for stability and specify aluminum alloys with high recycled content for the cladding.

- Performance Testing: Every window series is rigorously tested in third-party labs. We provide full certification reports, not just marketing claims.

- Global Support, Local Impact: We've supplied windows for projects from Toronto to Tokyo, but our engineering focus always starts with solving the specific thermal challenges of your location.

Conclusion: A Clear Investment in Comfort, Savings, and the Planet

The choice is no longer between aesthetics and efficiency, or between durability and sustainability. Aluminum clad wood windows deliver it all. They represent a fundamental shift from viewing windows as a commodity to understanding them as a critical, high-performance building system.

This investment pays dividends in multiple currencies: lower monthly utility bills, a more comfortable and healthier living environment, a significant increase in property value, and the profound satisfaction of directly reducing your environmental impact. Whether integrated into a new build or as part of a deep energy retrofit, they are a cornerstone of intelligent, future-proof design.

The data is clear, the technology is proven, and the need has never been greater. The question isn't whether you can afford to upgrade; it's whether you can afford not to.

Ready to Calculate Your Exact Savings?

Stop guessing and start planning with precision. Our team of sustainable solutions specialists can provide you with a custom performance analysis for your specific project, including estimated energy savings, product recommendations, and a clear quote.

Take the next step in your green building journey.

Get Your Free Project Assessment & Quote in 12 HoursNo obligation. Just expert insights to help you make the best decision.

Frequently Asked Questions (FAQ)

Yes, typically. While high-quality vinyl windows can be efficient, the best aluminum clad wood windows with advanced thermal breaks consistently achieve lower U-factors. The wood interior provides superior insulating properties compared to vinyl. Furthermore, aluminum-clad wood windows offer greater structural strength for larger glass expanses and have a more premium, durable feel that lasts longer without issues like warping or fading common in vinyl.

References & Further Reading

To deepen your knowledge, we recommend these authoritative resources:

- U.S. Department of Energy - Windows, Doors, and Skylights – Official government guide on window technologies and efficiency.

- National Fenestration Rating Council (NFRC) – The independent body that provides uniform window performance ratings (U-factor, SHGC, etc.).

- U.S. Green Building Council - LEED – Comprehensive resources on the LEED green building rating system.

English

English Russian

Russian